News Archives

Caltronics Design & Assembly Headlines

Caltronics Design & Assembly is committed to our community.

Please visit the corresponding pages for additional writings, resources, white papers, and our blog. You may also wish to follow our social media channels to keep up to date or stay in contact with us.

Caltronics Design & Assembly Recently Partnered With Bell Bank

Over the past 25 years, Cal and Cindy Houdek have grown their design and assembly business from just the two of them working at their kitchen table to a thriving company of 25 employees, with customers across all industries.

It wasn’t easy. But through hard work, determination and hiring the right people, the Houdeks reached the point entrepreneurs dreams of – where they could step back a bit, and everything would still run smoothly.

Then COVID-19 hit.

“We were all panicking – not sure what was going to happen,” remarks Cindy, President of Stacy, Minn.-based Caltronics Design & Assembly, an electronics partner for inventors, design engineers, and companies that need help getting products to market. “That was before we understood we had to stay open as an essential business.”

With stores emptied of safety supplies, Cal made hand sanitizer and Cindy sewed masks for their employees. At first they didn’t notice much difference beyond extra social distancing and cleaning precautions. A backlog of business kept them busy – for a time. But when only 5% of their customers remained open, Caltronics’ workload slowed drastically.

Then came messages from customers unable to pay their bills. With the drop in income, it seemed more difficult decisions were ahead.

“We really needed to keep all of our people,” Cindy notes. “Good talent is hard to find.”

ALL HANDS ON DECK

It was early July before business started to pick up again. In the meantime, Cindy had started working with their banker in April on ways to weather this unprecedented and unimaginable storm.

Chad Lindgren, President of Bell Bank’s north central market, talked to Cindy about the Small Business Association’s (SBA) Paycheck Protection Program (PPP), which was offering federally guaranteed loans to help businesses keep workers employed amid the pandemic and economic downturn. Borrowers who followed certain requirements could also apply for loan forgiveness.

Banks were scrambling. It was a new program, and many bankers had more questions than answers. But Bell did not hesitate.

“Very early on, our executive management team wanted to get this rolled out and provided the tools to put it together,” says Paul Flood, Bell’s SBA Lending Manager and a veteran SBA lender.

Employees from other departments asked how they could help and were trained to assist, allowing bankers to process more than 1,300 loans in the first week the program became available.

“End to end, it was an unbelievable feat of teamwork,” confirms Paul, who had only been working for Bell two weeks before the PPP process started. “It was awe-inspiring to be involved in something like that. I’ve worked for big banks where their claims of competitive advantages rang hollow. It was so refreshing to experience Bell’s level of teamwork.”

MORE THAN A JOB

Around this time, Chad met with a business owner who was frustrated over how long his PPP loan was taking at another bank and that he hadn’t heard from his banker in a week.

“I asked him to give Bell a chance,” Chad remarks. “When I called him back an hour later with his SBA number, he was shocked – and so happy that he switched his accounts to Bell.”

Many of Bell’s employees spent all of their waking hours, seven days a week for a month, working on PPP loans.

“I would roll out of bed, sign on with cup of coffee and go until 11 or 12 at night,” Chad recalls.

But for bankers like him, it wasn’t about the long hours or number of loans they were processing – it was about helping businesses keep people employed, so they could take care of their families.

Chad wasn’t only managing client relationships; like many bankers, he also spent countless hours collecting supporting materials, entering applications, and getting approvals.

“Honestly, it felt more like a calling than a job,” Chad explains. “When you look at the impact, I think I helped nearly 900 employees keep their jobs. That’s what motivated me to keep going every day. It gave me so much purpose. It was really incredible to be part of.”

As of mid-July, Bell had processed over 3,200 PPP-approved loans, helping more than 70,000 people keep their jobs.

SIMPLE, BUT SIGNIFICANT

At Caltronics, the spring and early summer of 2020 was a stressful time for everyone. But the PPP loan they got through Bell helped them continue to pay – and keep – their employees.

“It was nice to know we had that loan we could fall back on,” Cindy affirms. “And it was comforting to know Chad would take care of us. Even if we wouldn’t have qualified for a PPP loan, I knew Chad would have stepped up and given us another loan.”

With everything else that was happening, Cindy appreciates that the loan process was so simple. “Chad and the team at Bell made it easy,” she notes. “As a business owner, if you don’t have a strong relationship with a good banker – someone fighting for and believing in you – it’s a struggle.”

It was a time of pivoting on the fly for both Bell and Caltronics, where adjustments were needed to weather the COVID-19 storm. While neither company had been through anything like this before, both are forging ahead into a stronger tomorrow.

ABOUT BELL BANK

Founded in 1966 and headquartered in Fargo, N.D., Bell Bank is one of the nation’s largest independently owned banks, with full-service banking locations in Minnesota, North Dakota, and Arizona and more than $8 billion in assets. Bell opened its first Twin Cities banking location west of downtown Minneapolis in 2012, subsequently adding full-service banks in Woodbury, Stillwater, and Maple Grove and loan production/deposit production offices in Bloomington and White Bear Lake. In July 2020, Bell opened an additional full-service location in Forest Lake.

Bell’s experienced bankers understand the complex, ever-changing needs of manufacturing companies. With low banker turnover due to its people-first culture and growth-oriented workplace, Bell delivers dependability and continuity in banking relationships. Along with high-touch service, clients find a depth of resources and capabilities often associated with much larger banks, as well as specialization and expertise in both personal and business-related banking matters.

The Star Tribune named Bell Bank as the #1 Top Workplace in large companies in 2019 and 2020. Bell has also been recognized by Forbes as a Best-in-State Bank in Minnesota and on the World’s Best Banks list. The bank has also received multiple Community Impact Awards by Minnesota Business and a Progress Minnesota Award by Finance & Commerce. To find a banker or learn more about Bell Bank, visit bell.bank.

TO LEARN MORE about Bell Bank, member FDIC, or find a commercial banker, visit bell.bank or call 1-800-450-8949. Learn about Caltronics at caltronicsdesign.com.

Caltronics donation aims to build student interest

With a plan to build a relationship with local schools to help the students understand that manufacturing encompasses many different jobs, Caltronics Design and Assembly, Inc. designed and built a printed circuit board to donate to the high school electronics class.

Caltronics is a contract manufacturer of electronic components based in Stacy, MN. Cal and Cindy Houdek are the owners and started the company in 1995. The idea for the circuit board donation to Rick Arvidson’s electronics class came about when Caltronic’s production manager Ron Hammer got the idea to talk to schools in the area to let them know the company is looking for future employees. Cal Houdek called Arvidson to find out what teaching tools he used in his class. He learned that Arvidson was buying kits online. Cal, a degreed engineer, felt he could come up with a new design to help the kids get a better understanding of the way electronics work. Cal and Cindy dropped off the kits to Mr. Arvidson’s class on April 25 and spoke to the class about the engineering and manufacturing Caltronics does each day.

This article originally appeared June 7, 2017 in Forest Lake Times (article courtesy of editor, Jason DeMoe).

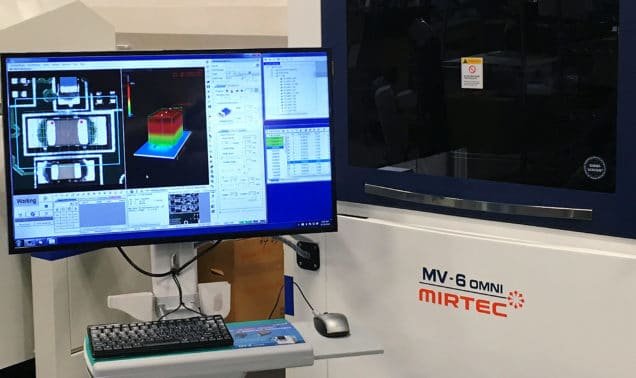

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016

Circuit Board Visual Inspections just got that much better with our newest addition, the MIRTEC MV-6 Automated Optical Inspection Machine.

Caltronics is proud to announce our purchase of a new MIRTEC MV-6 Omni 3-D automated optical inspection (AOI) machine for PCBA inspection. Since purchasing our first MIRTEC AOI machine in 2008, Caltronics has seen the most common resistor sizes drop from 0805 to 0402 and other components have reduced in size as well.

Improving visual inspection was a key driver with the new machine’s 15-megapixel camera and 3-D system, Caltronics is equipped to provide excellent Printed Circuit Board Assembly (PCBA) quality control for device placement and soldering inspection well into the future.

The MV-6 has multiple inspection tools to help solve more issues than past inspection tools

Caltronics purchased the MV-6 ONI 3D AOI machine in order to improve the quality of their PCBs. There are two inspection tools on this AOI machine: 2D and 3D. The two-dimensional function of the machine helps by identifying missing components, incorrect components, components that are not aligned properly, polarity issues, tombstoning (when a component tilts up at one end), bridging (when too much solder is used and connects two or more pads), parts that are flipped and when there isn’t enough solder put on the board for the components it contains. The 3D aspect of the AOI machine helps with issues like the height of components, proper positioning of components when thermal issues cause pad lifting or insufficient solder.

Repairing Circuit boards before the final visual inspection helps quality and production time.

In purchasing the MIRTEC MV-6, Caltronics adds a computerized method to confirm quality in addition to the visual inspection we have been doing. Using the MIRTEC, the technicians no longer have to view the parts on circuit boards through microscopes and can view the images of the board and components on the board on an expanded computer screen, having the ability to zoom into known areas of concern or areas that the MIRTEC identifies as questionable. The technician can then repair the board before it goes to the final inspection.

To Learn More Contact Caltronics

We’re always improving our machines to help create a solution quicker, faster, and less expensive for you to take to market. If you’re looking to design or manufacture an electronic product we can help. We have the tools and talent to build and assemble your next project. Contact us or give us a call at 651.462.1440 today to get started!