Design for Test

How Does Design for Test Change The Way Your Product Is Made?

Design for Test: Planning for Your Project

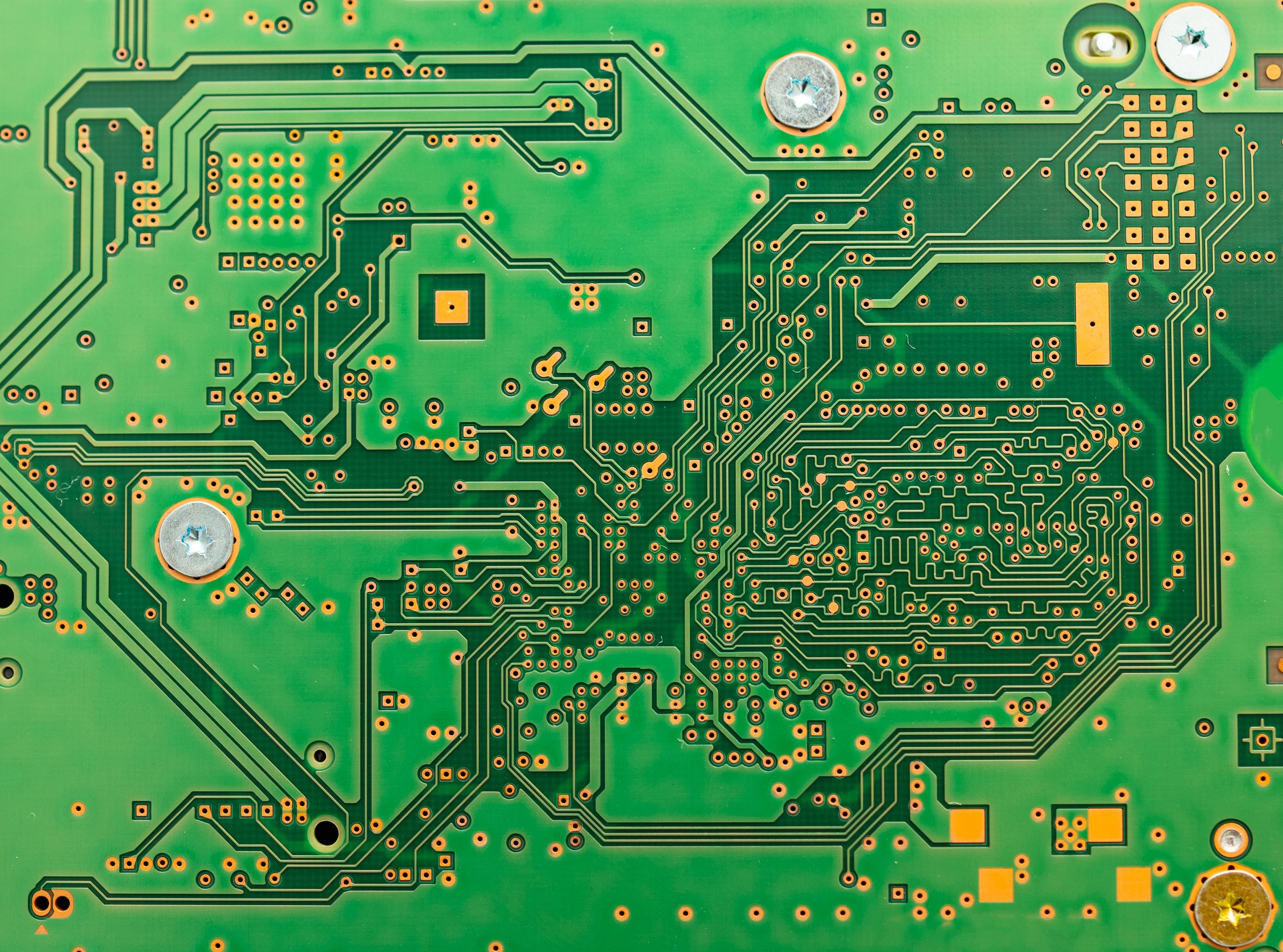

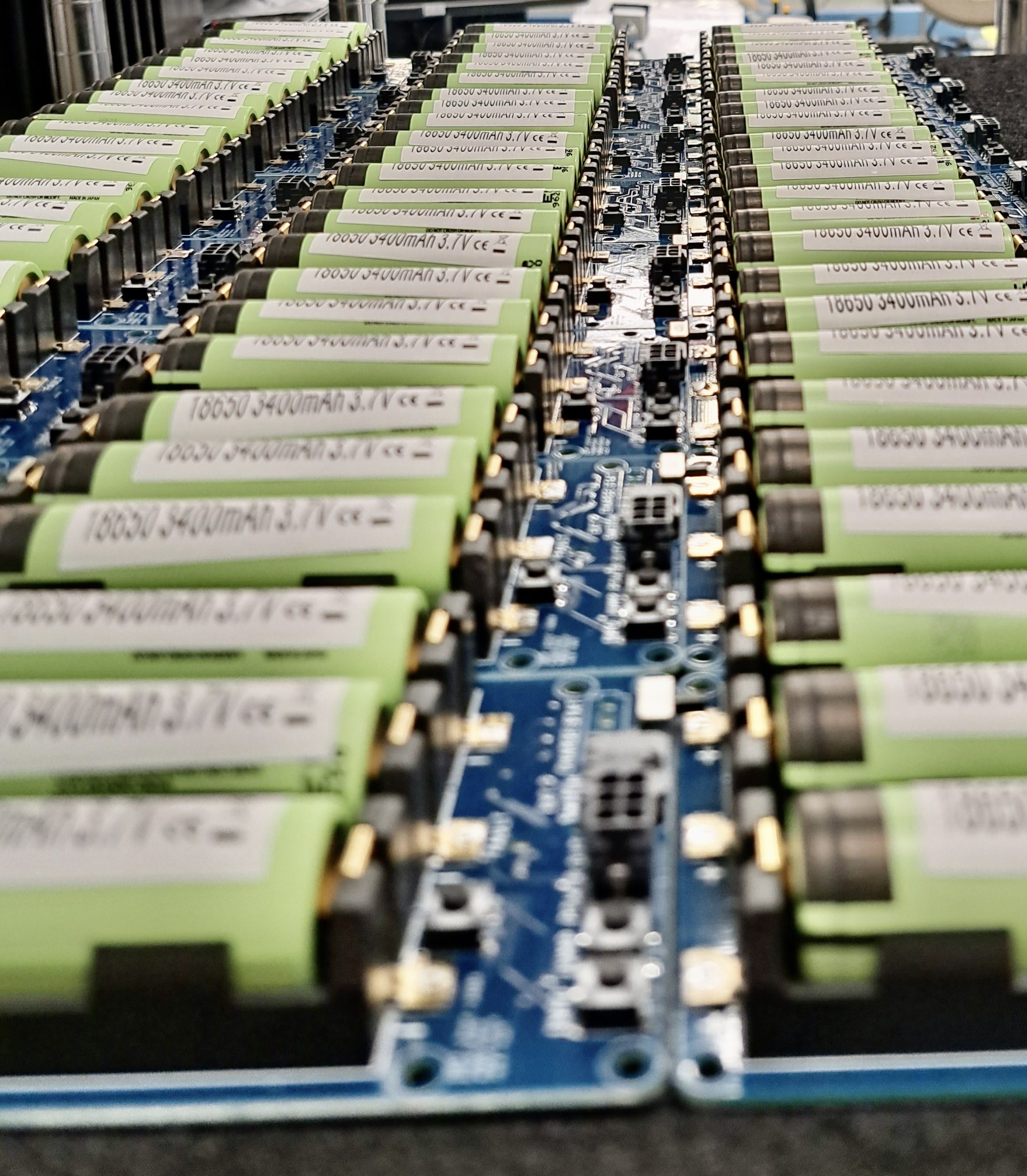

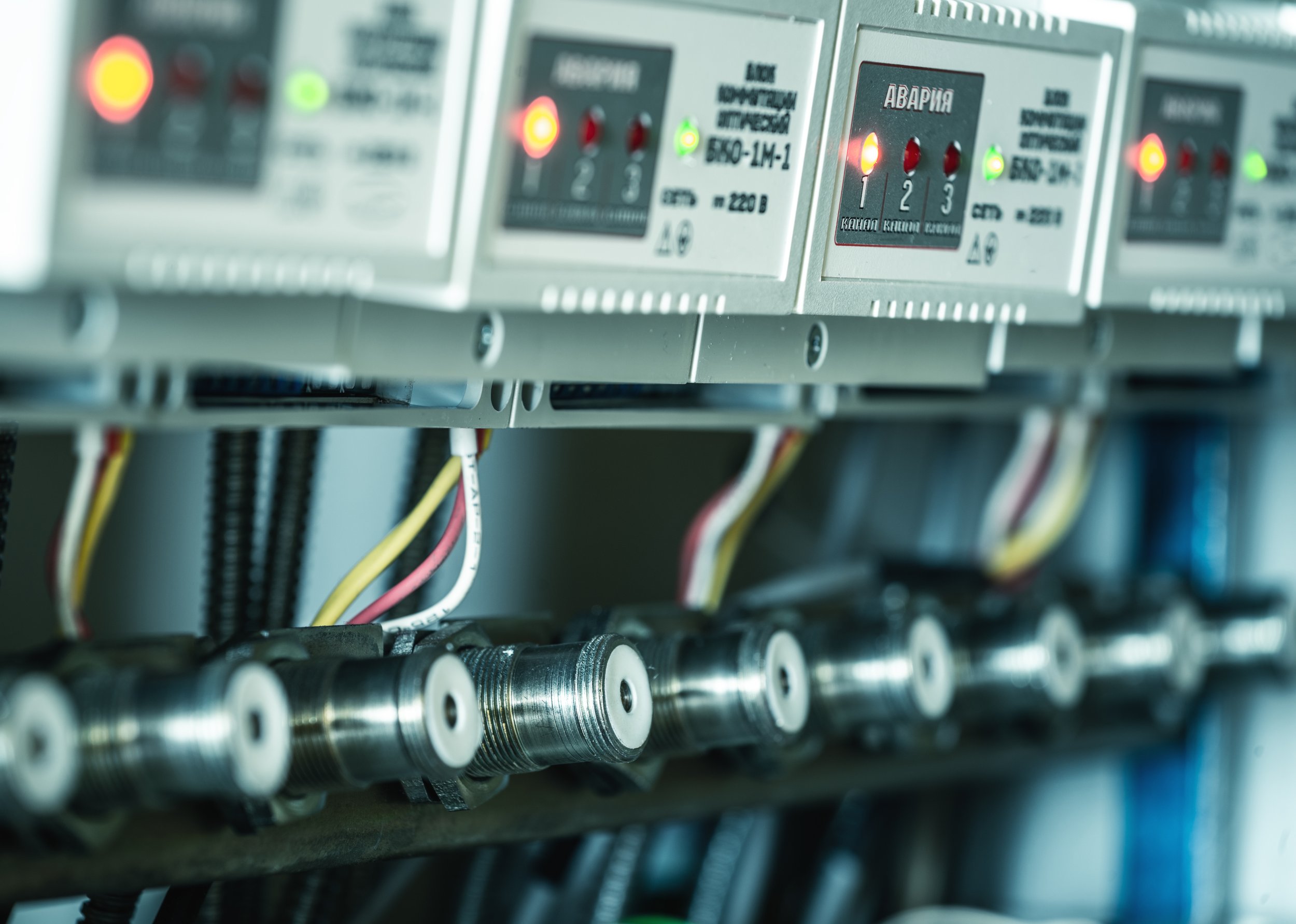

Caltronics testing and inspection are vital to the production of electronic parts. When assembling your product, it must conform to the design specifications established before assembly to prove those design specifications are functional. Inspections and testing can become very expensive during the design phase if treated as afterthoughts.

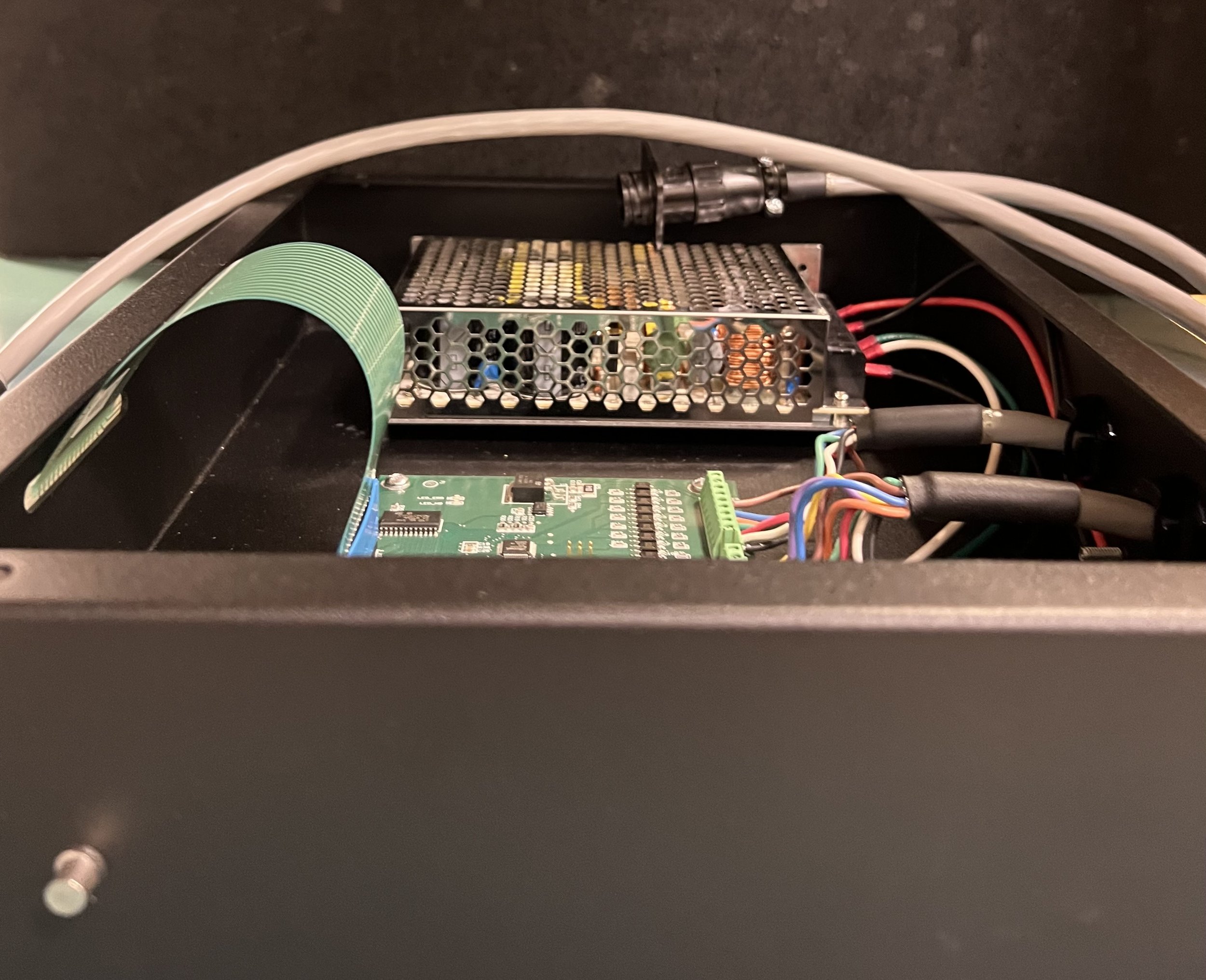

Our design for test (DFT) production strategy ensures that the original electronics design incorporates the specifications to produce a functional and high-performing product without the added expense of multiple designs and test stages.

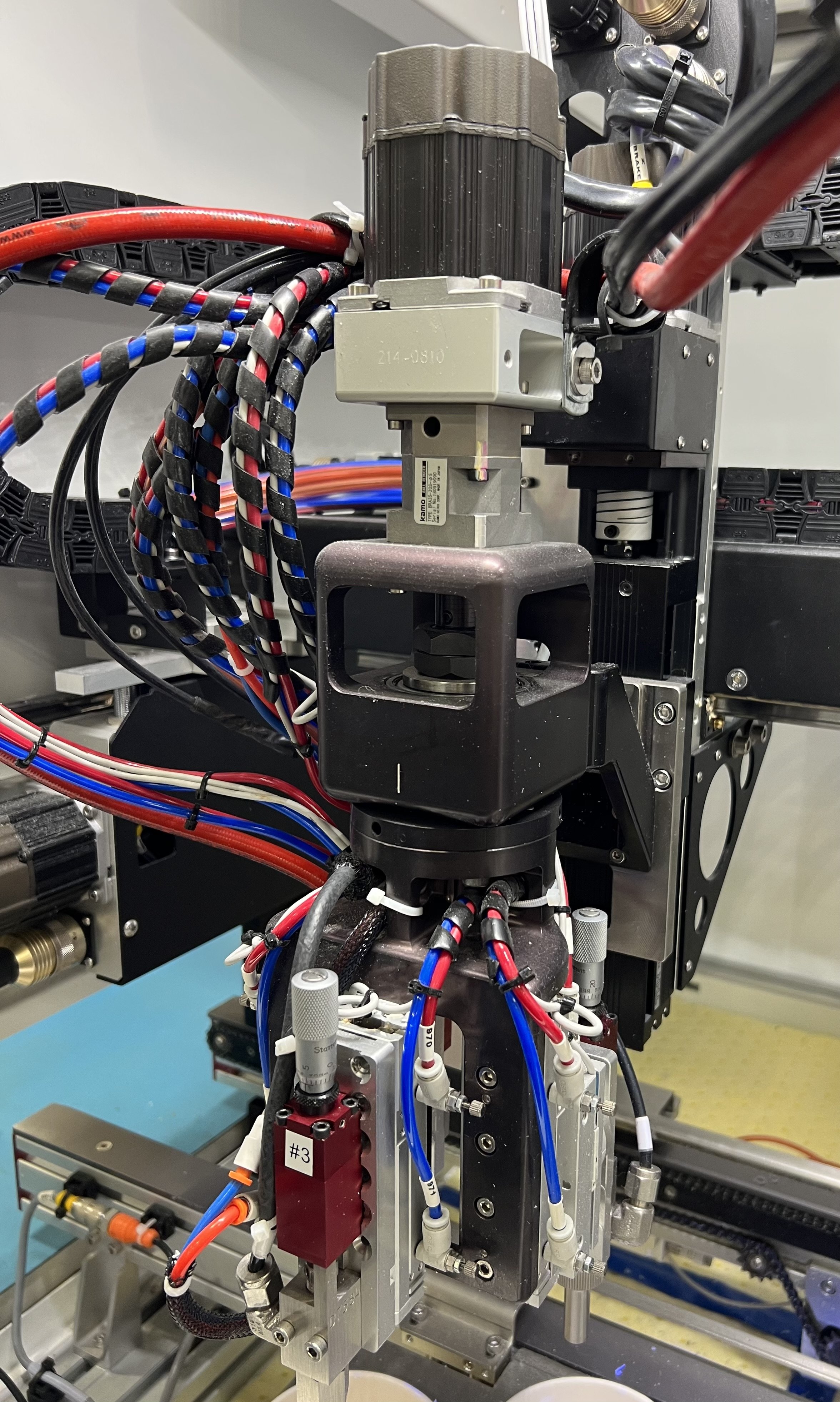

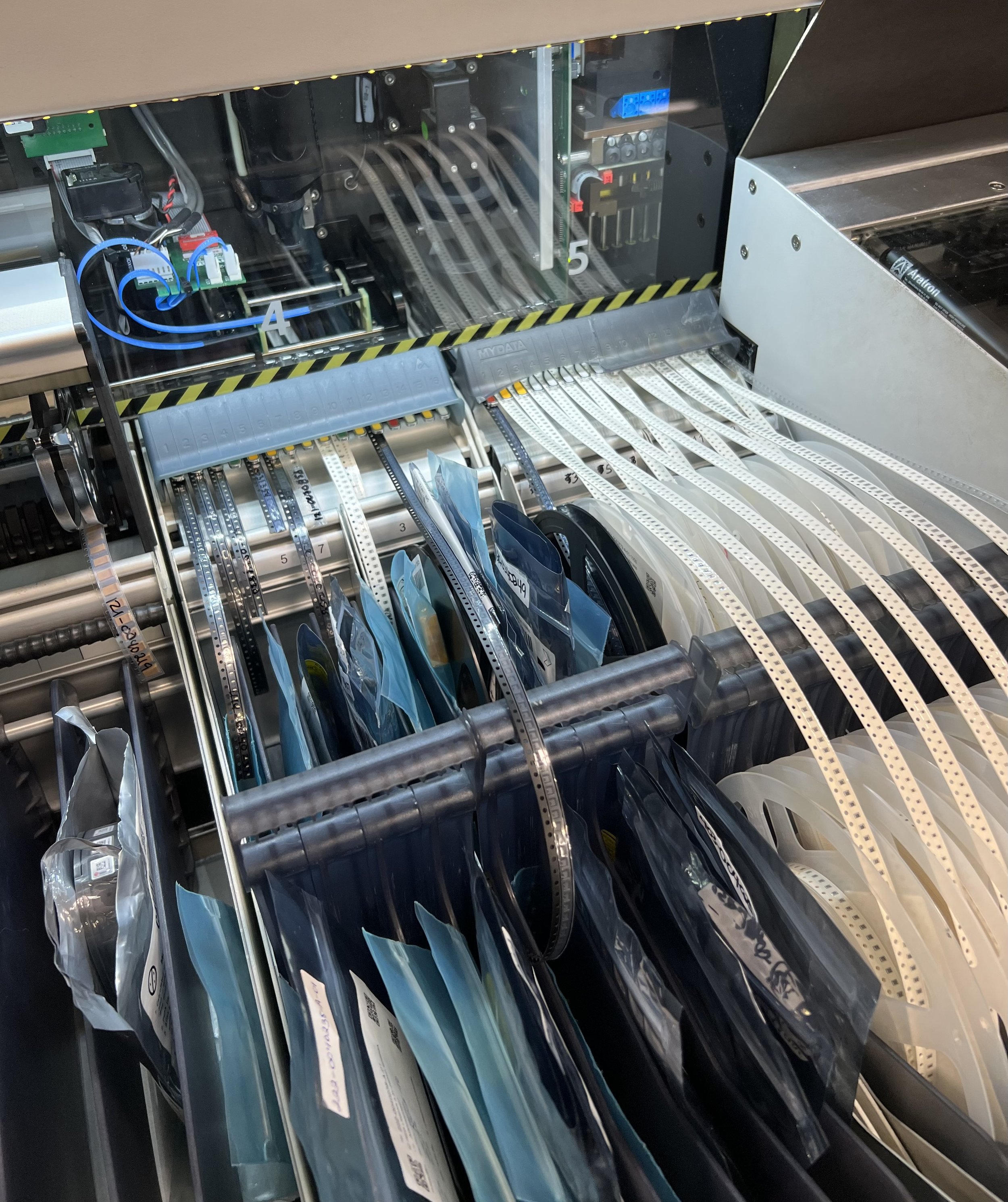

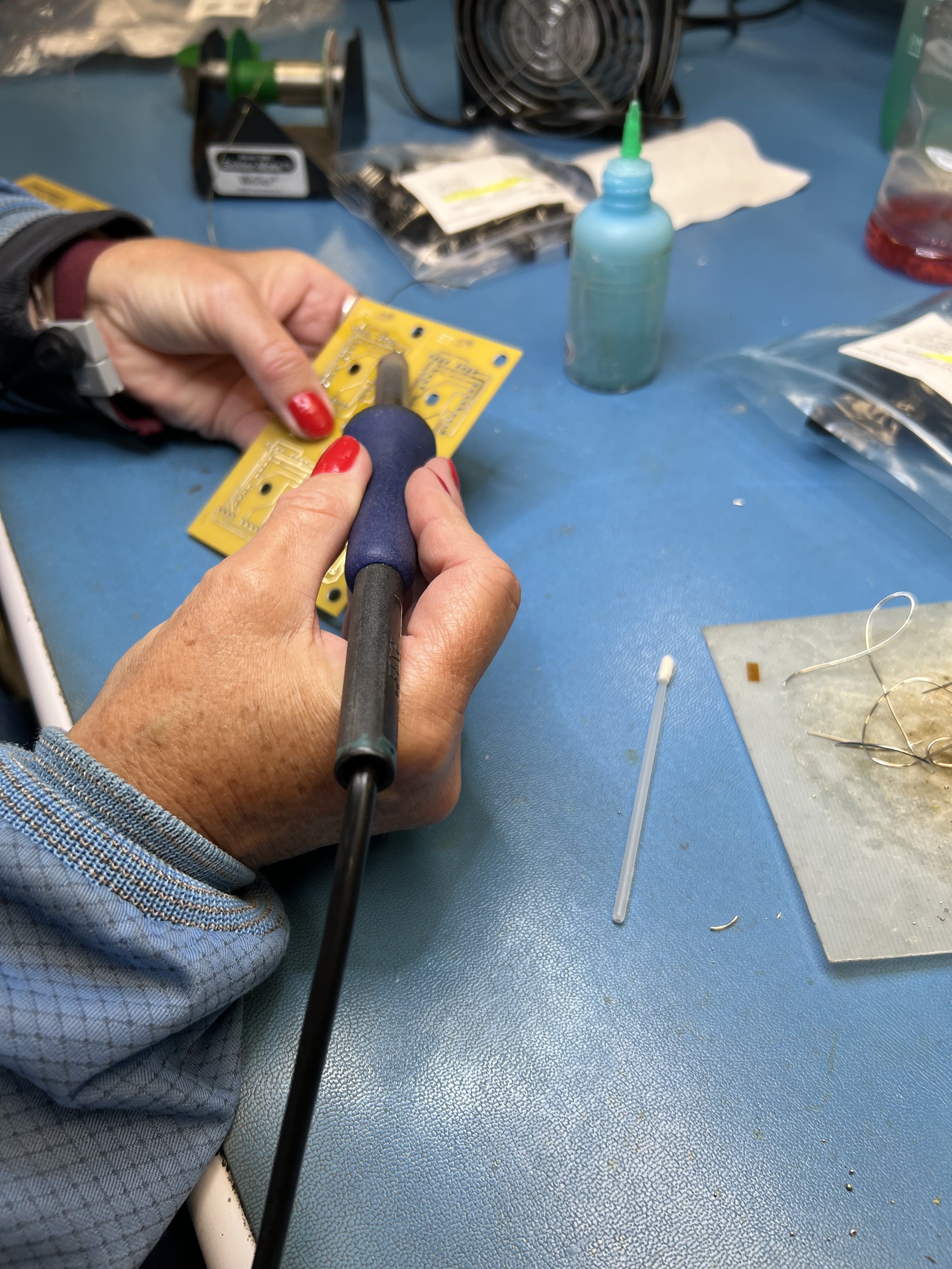

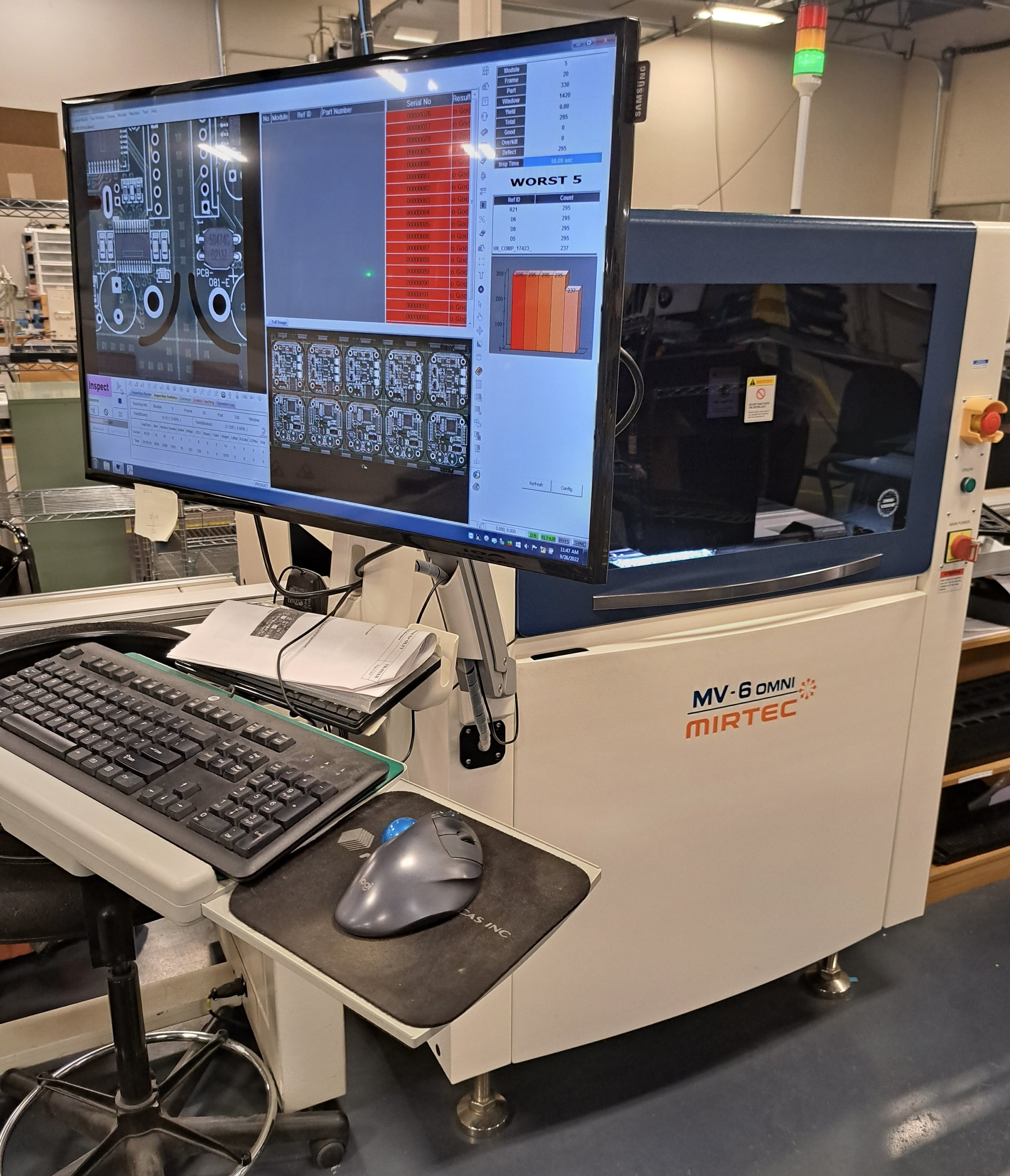

Inspection and testing can go from expensive and time-consuming to cost-efficient quality assurance procedures using the Caltronics design for test methods. Our team is heavily proactive about design for test methods to ensure each product is designed for in-line inspection and efficient testing by our trained test technicians per the requirements set in the design process.

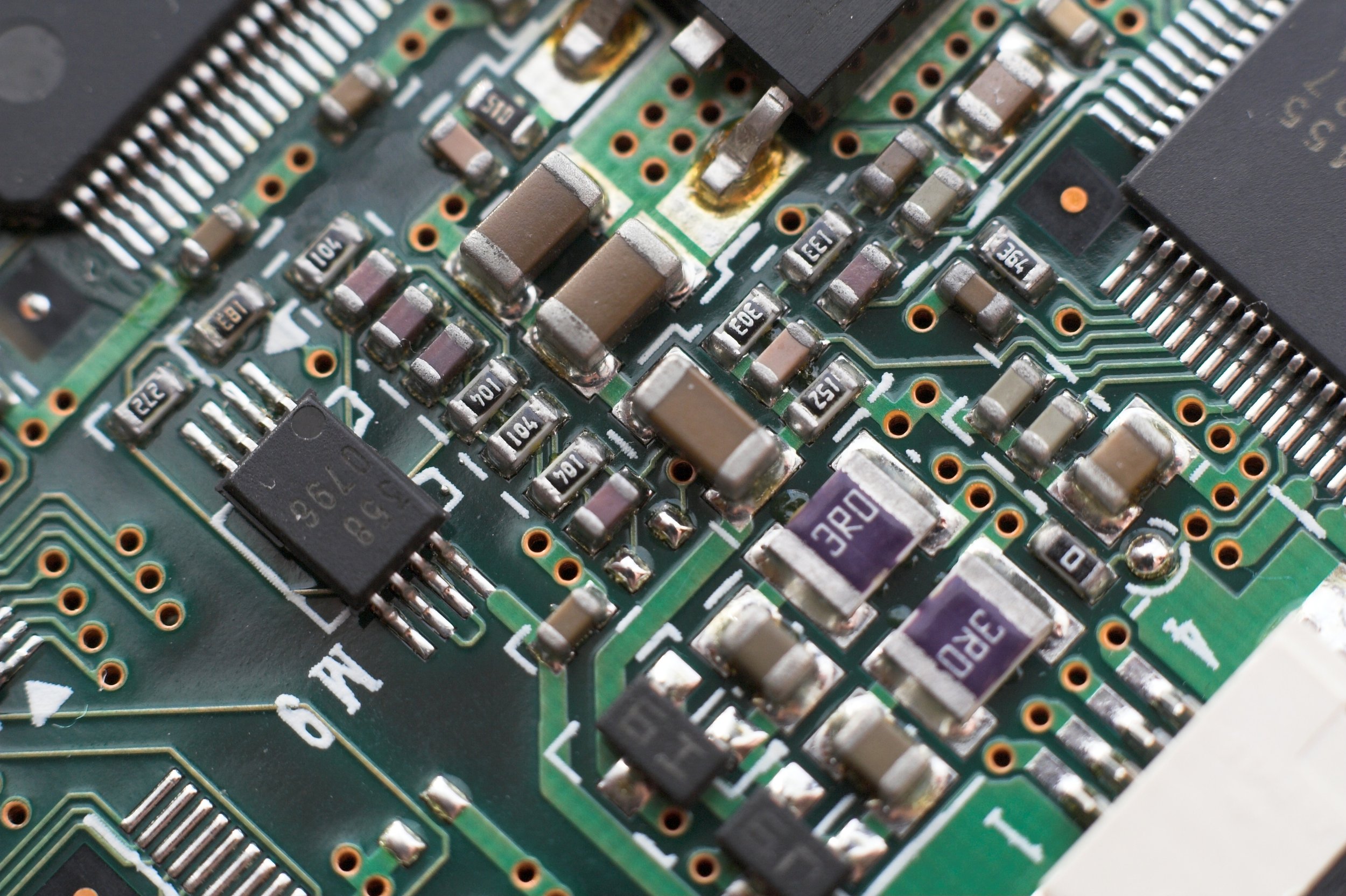

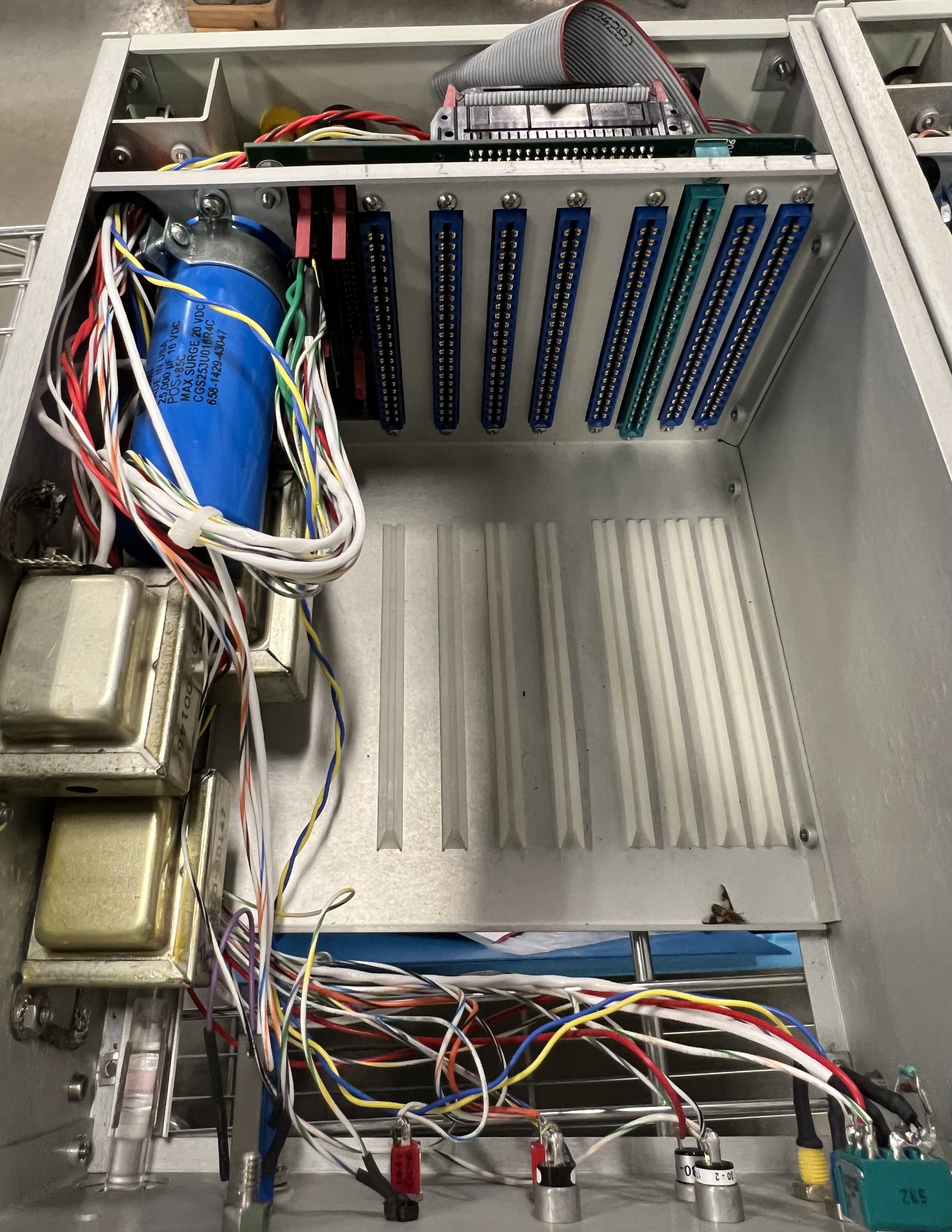

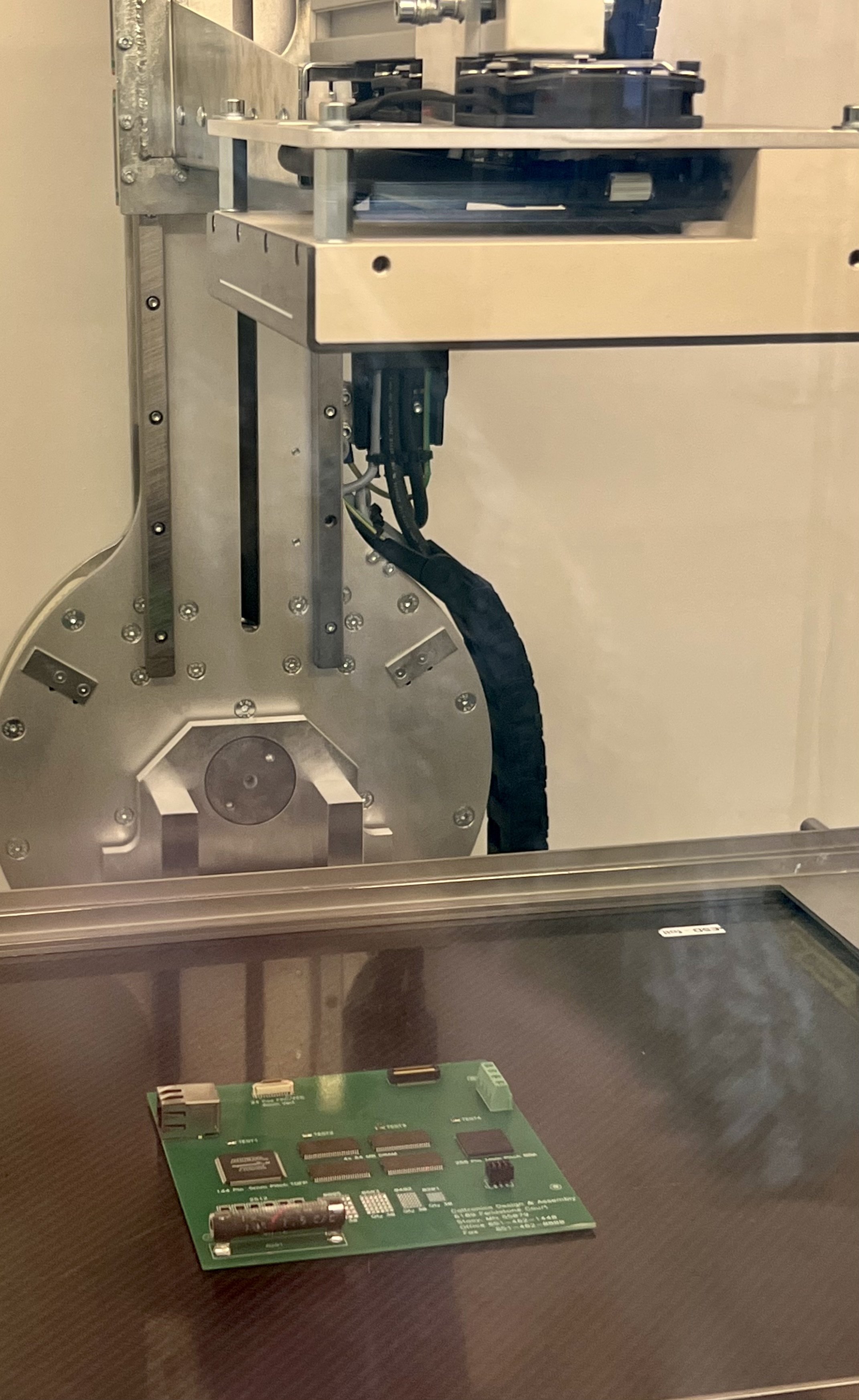

Our product designs are completed with production in mind, so it takes fewer steps to deliver a finished product. When the most efficient routing is found for the job, our design for test method begins by considering how the board should be assembled. These deep and in-depth analyses are then incorporated during the design phase, so when it comes to testing designs in manufacturing, your electronics designs are equipped with the specifications to streamline testing and move into production.

In-depth analyses of how the PCB should be assembled.

Test the board's electronic capabilities and ensure it works as originally designed.

Seek customer approval, receive provided feedback, then begin at step one again until completed.

Caltronics Gives Power to the Consumer

We further practice the design for test strategy through an extensive design approval process by leveraging close working relationships and strong communication with you, our customers, at every stage of the project design process. This process guarantees that our design engineering team clearly understands the required design inputs established by customers. At each stage of development, the customer approves or provides feedback on the project.

Industries We Work In

Common Questions Around the Design for Test Method

How does design for test accelerate the production process?

What projects use the design for test method?

The design for test method begins with the end in mind. It accelerates the production process by,

Keeping the end goal in mind from the start helps us create the necessary specifications throughout the entirety of the process.

Our process moves fast because the setup is already equipped with details to manufacture the final product.

For simple to complex projects, we use this method to save money, time, and resources throughout the project.

Caltronics Won’t Let You Leave Testing as an Afterthought

If you have a product in mind, let Caltronics and the design for test method get you there. We keep the final product in mind at every stage to eliminate costly inspections and multiple testing trials, we’re your partners from start to finish.