Electronic Testing

Caltronics’ Electronic Testing in PCB Design

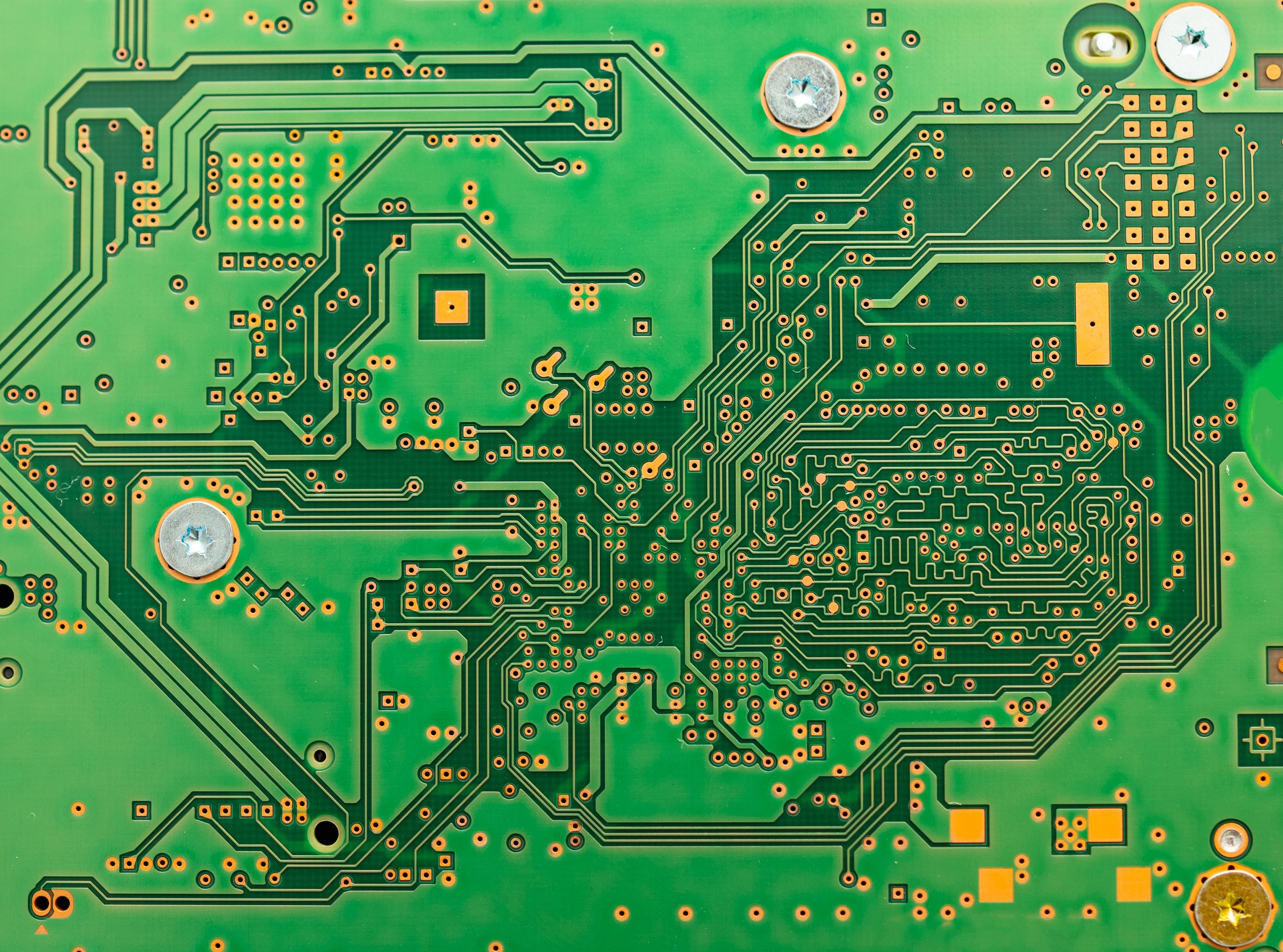

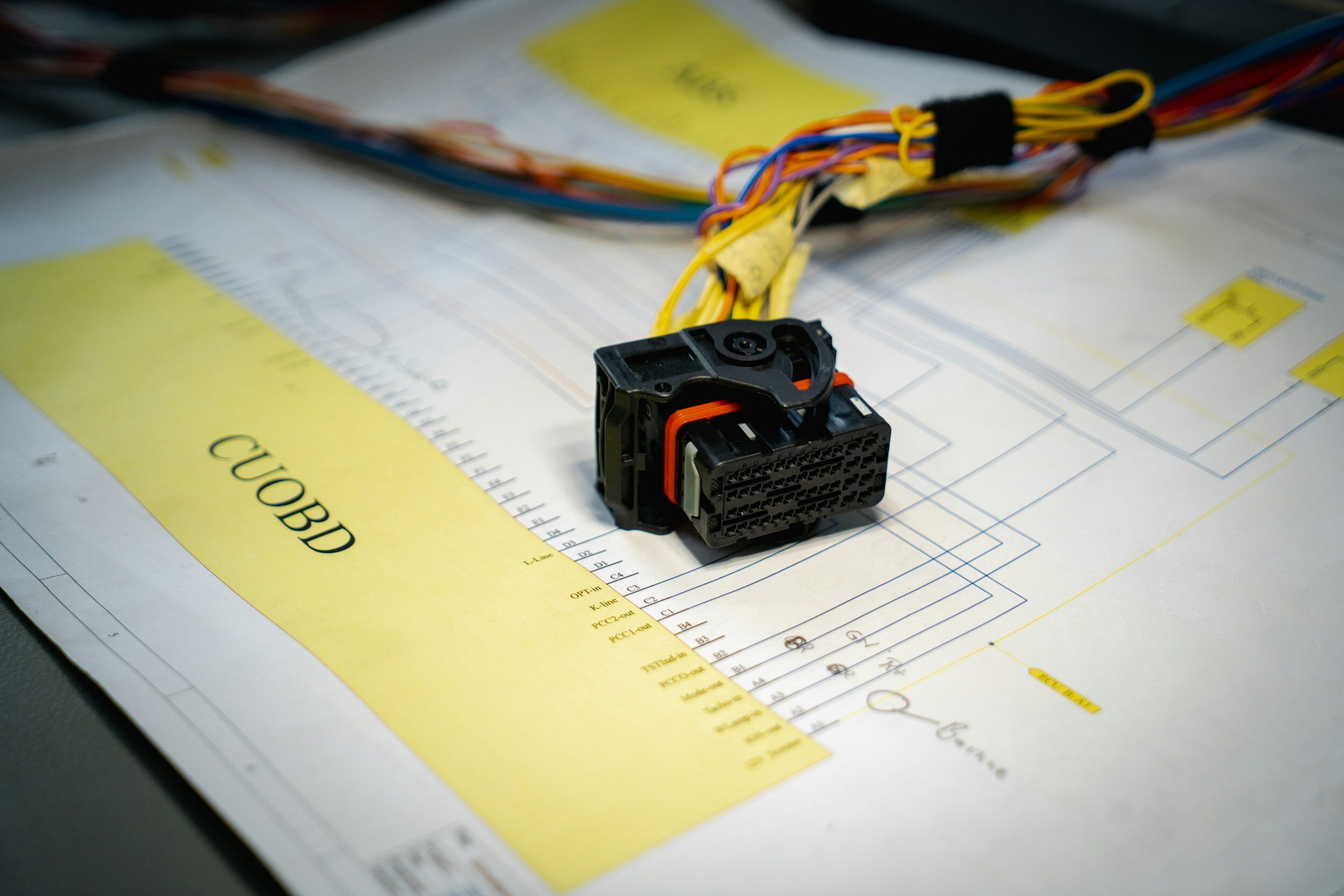

Electronic Testing and PCB Inspection

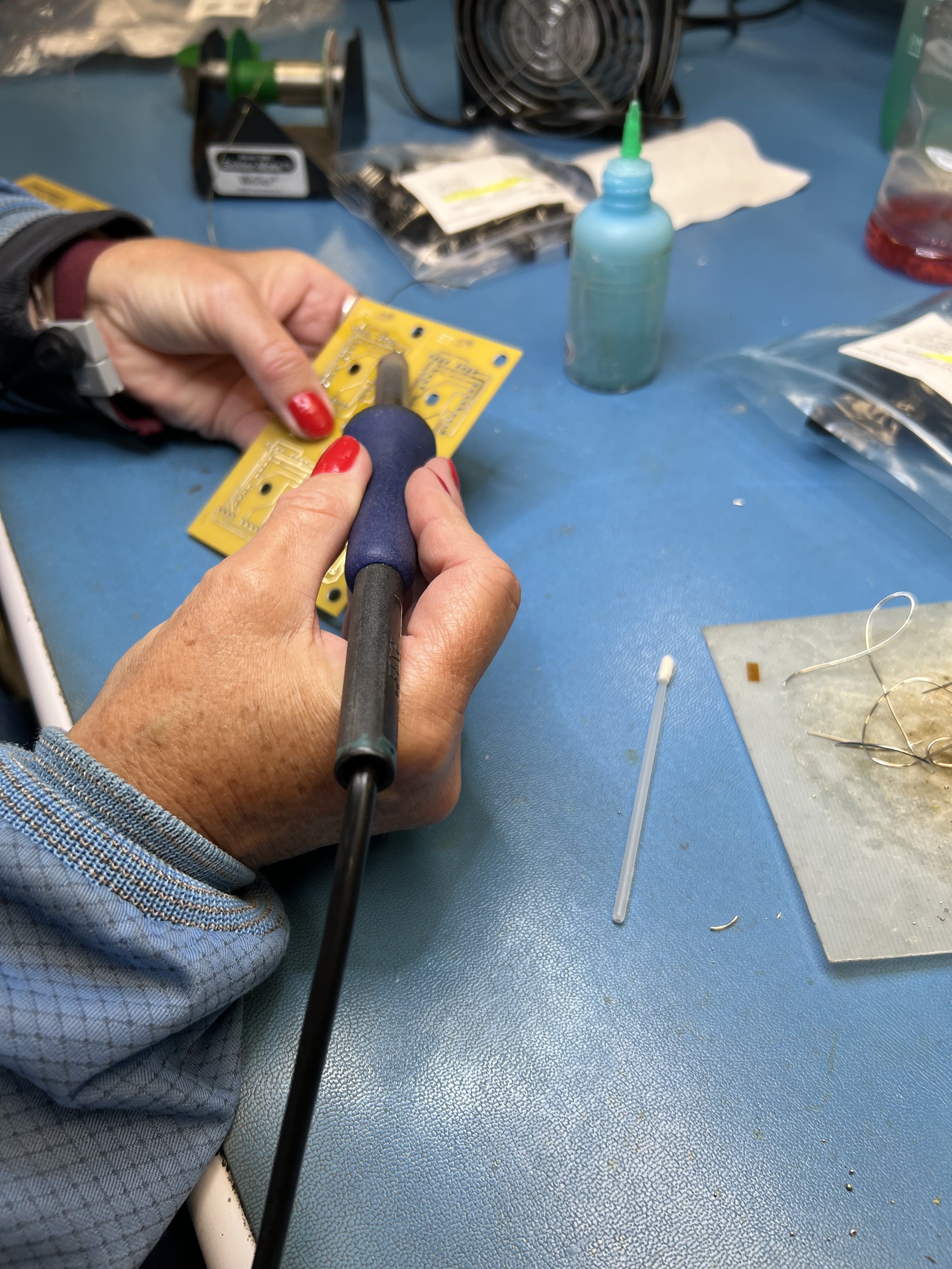

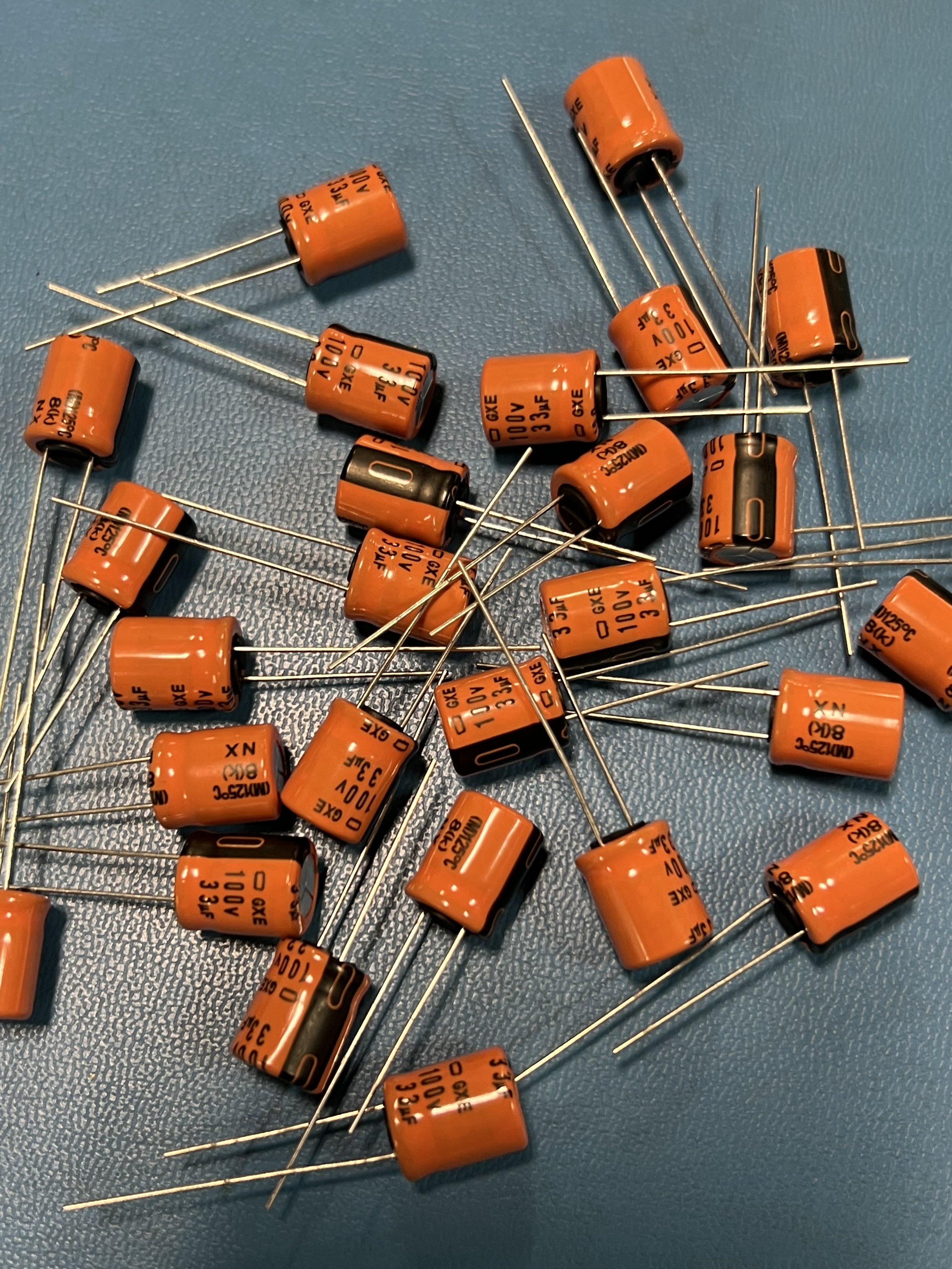

Electronic testing and thorough inspection are how we at Caltronics demonstrate that finished goods live up to their specs. Most industry leaders put these actions as the final stages of the manufacturing process, but at Caltronics, we inspect and test the electronic plan early in the development process.

Electronic testing helps our team uncover problems and find solutions. We are developing new standards in the PCBA industry. Let Caltronics lead the way for your next project in electrical design, printed circuit boards, and more.

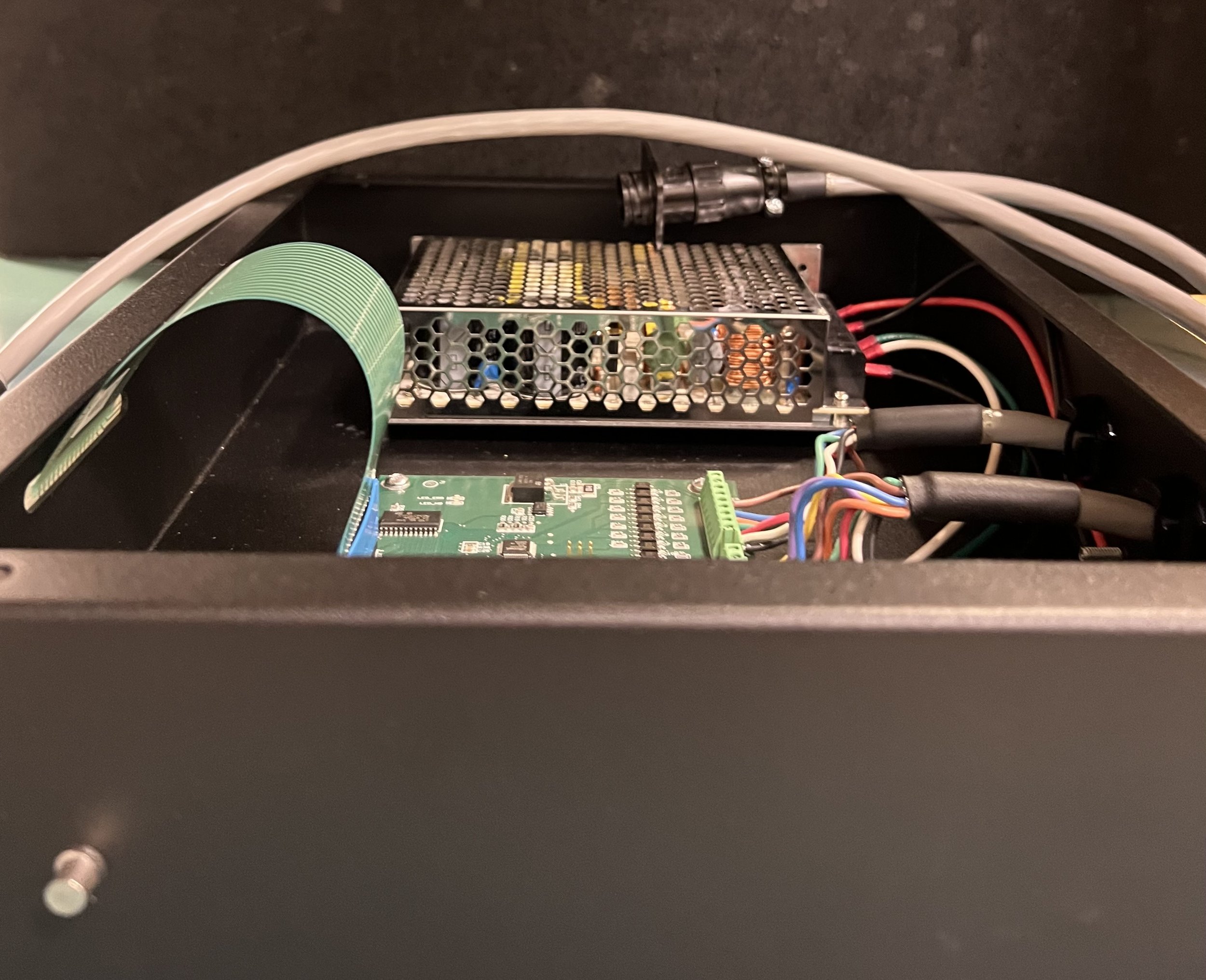

The Caltronics testing process ensures that your products meet industry standards while being on time and without sacrificing quality. Our technicians pride themselves on applying cutting-edge technology to guarantee that we meet your exact specifications.

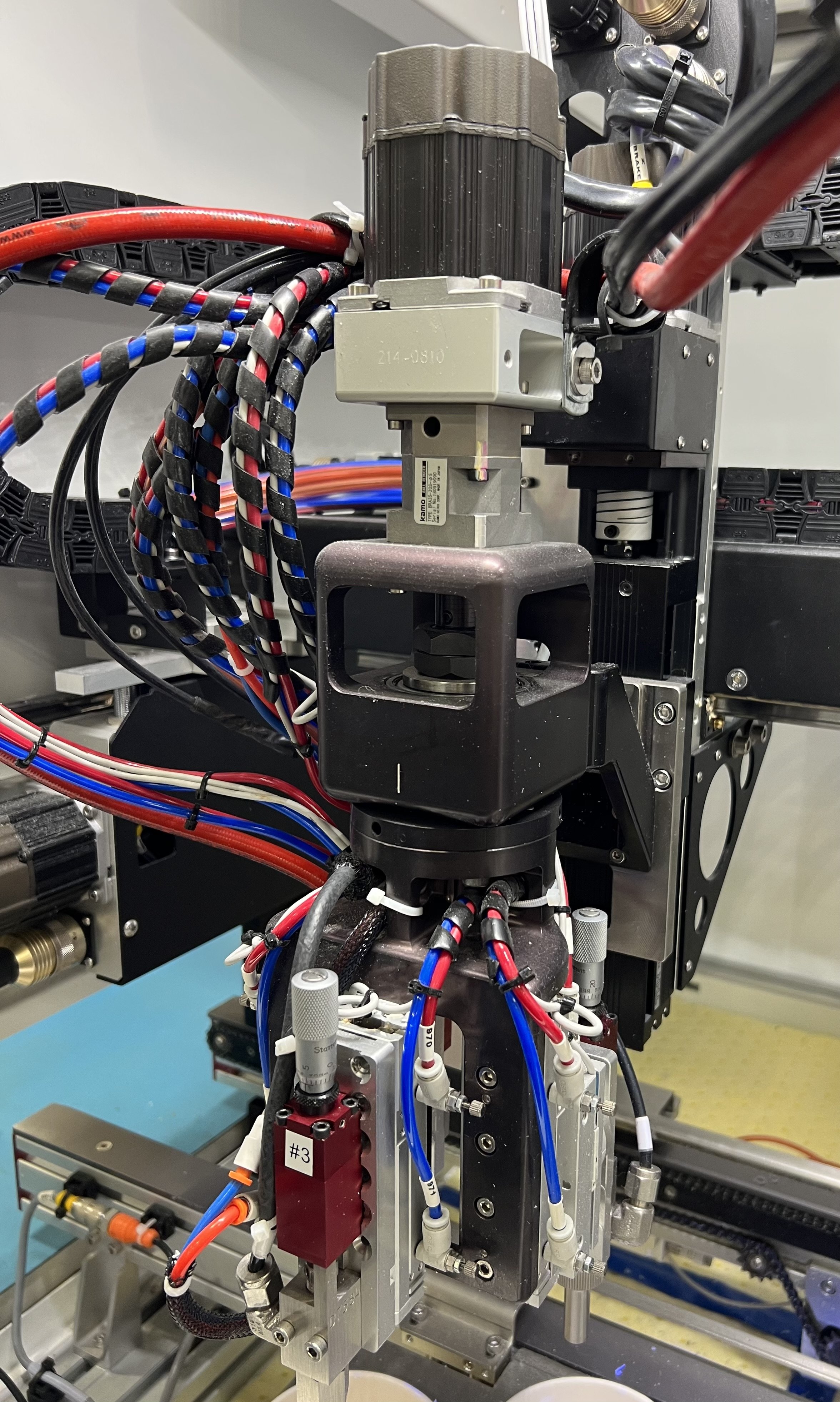

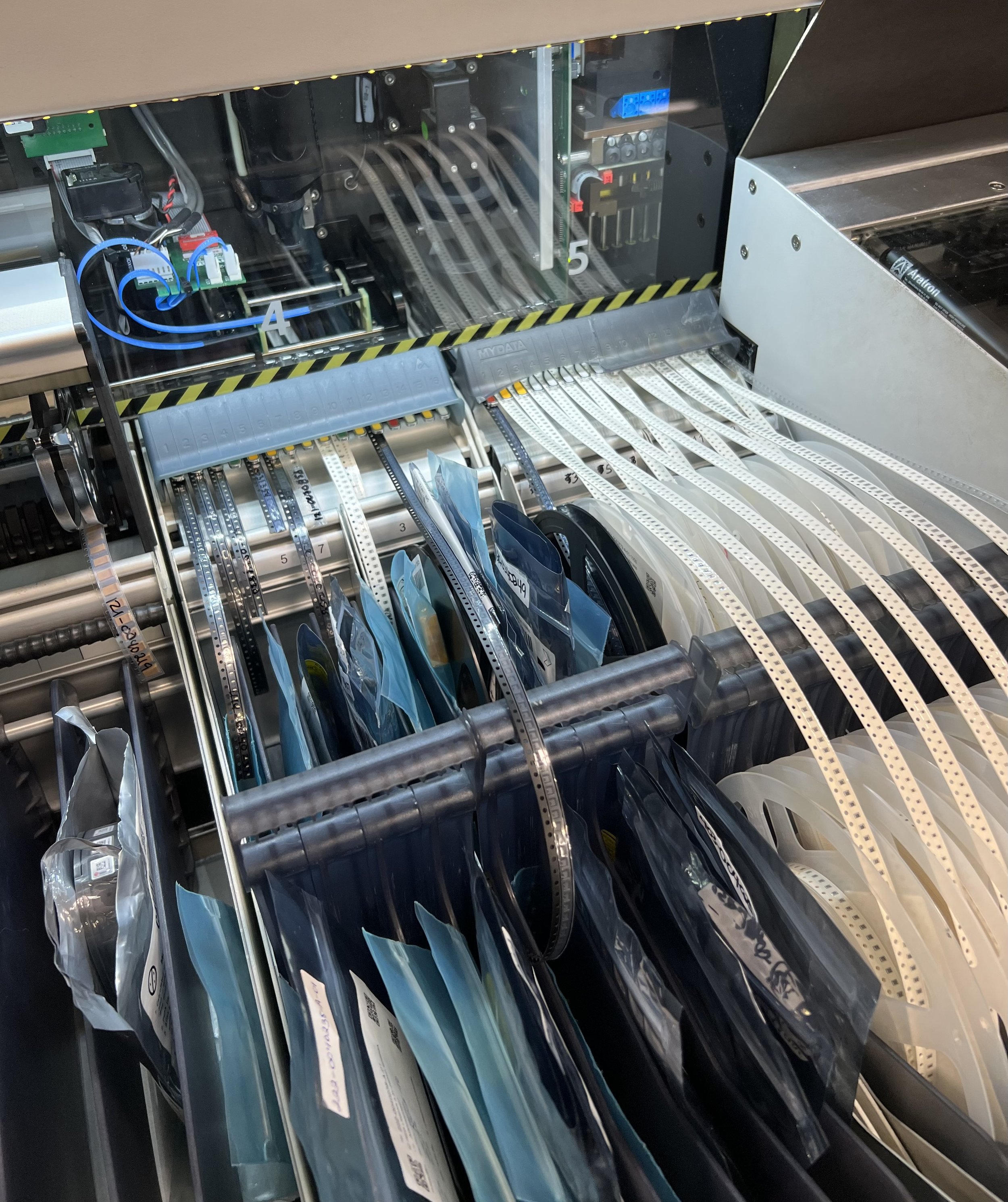

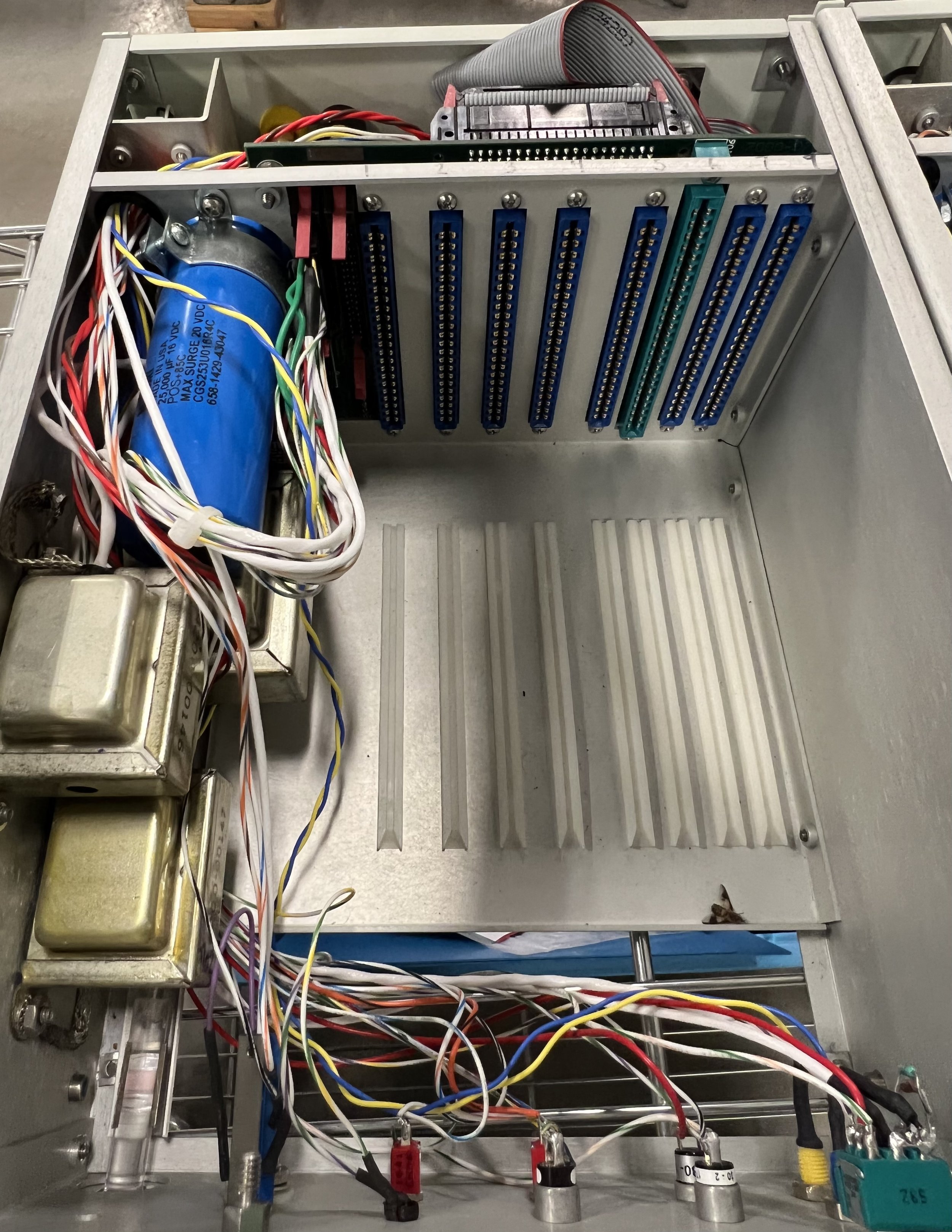

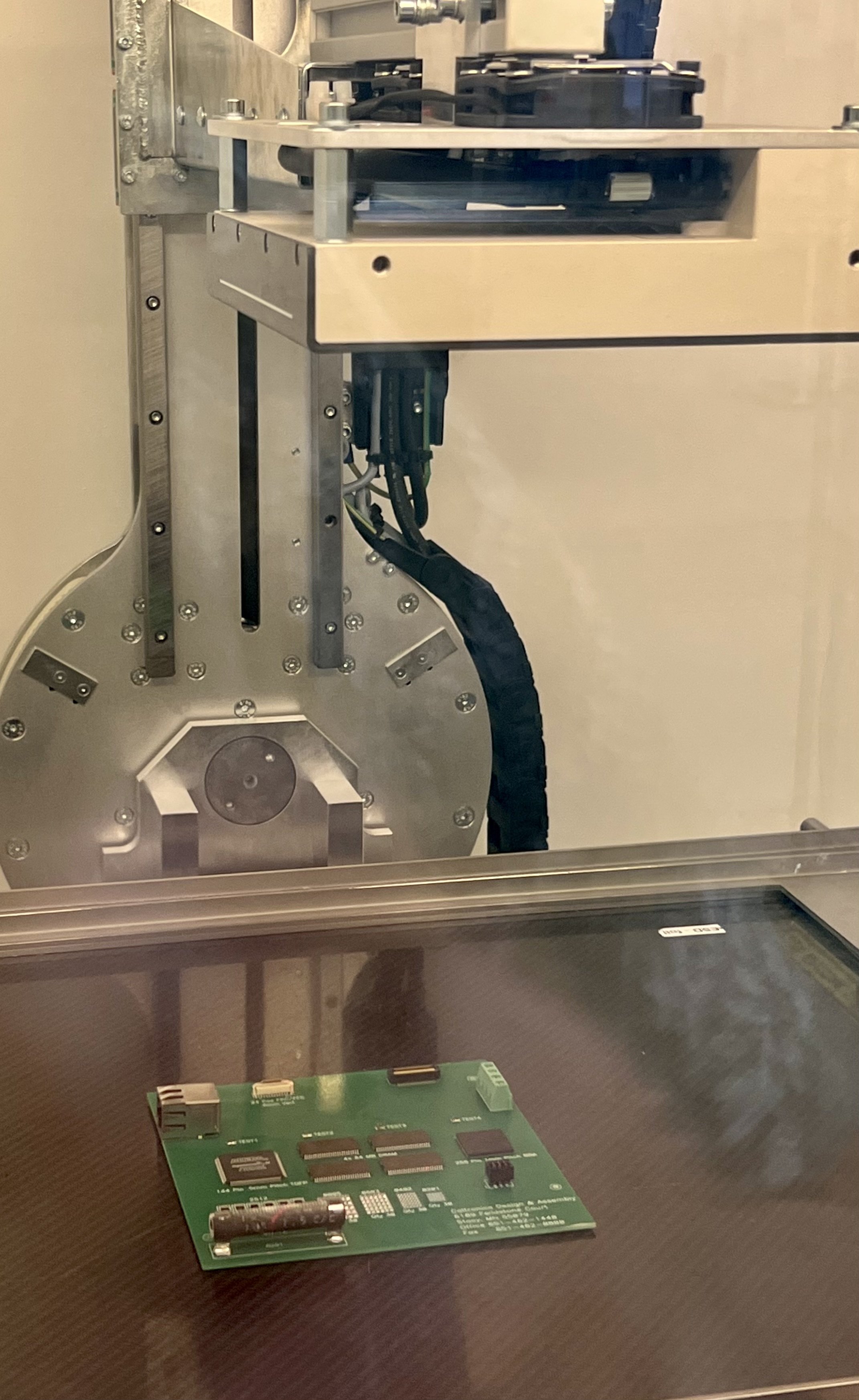

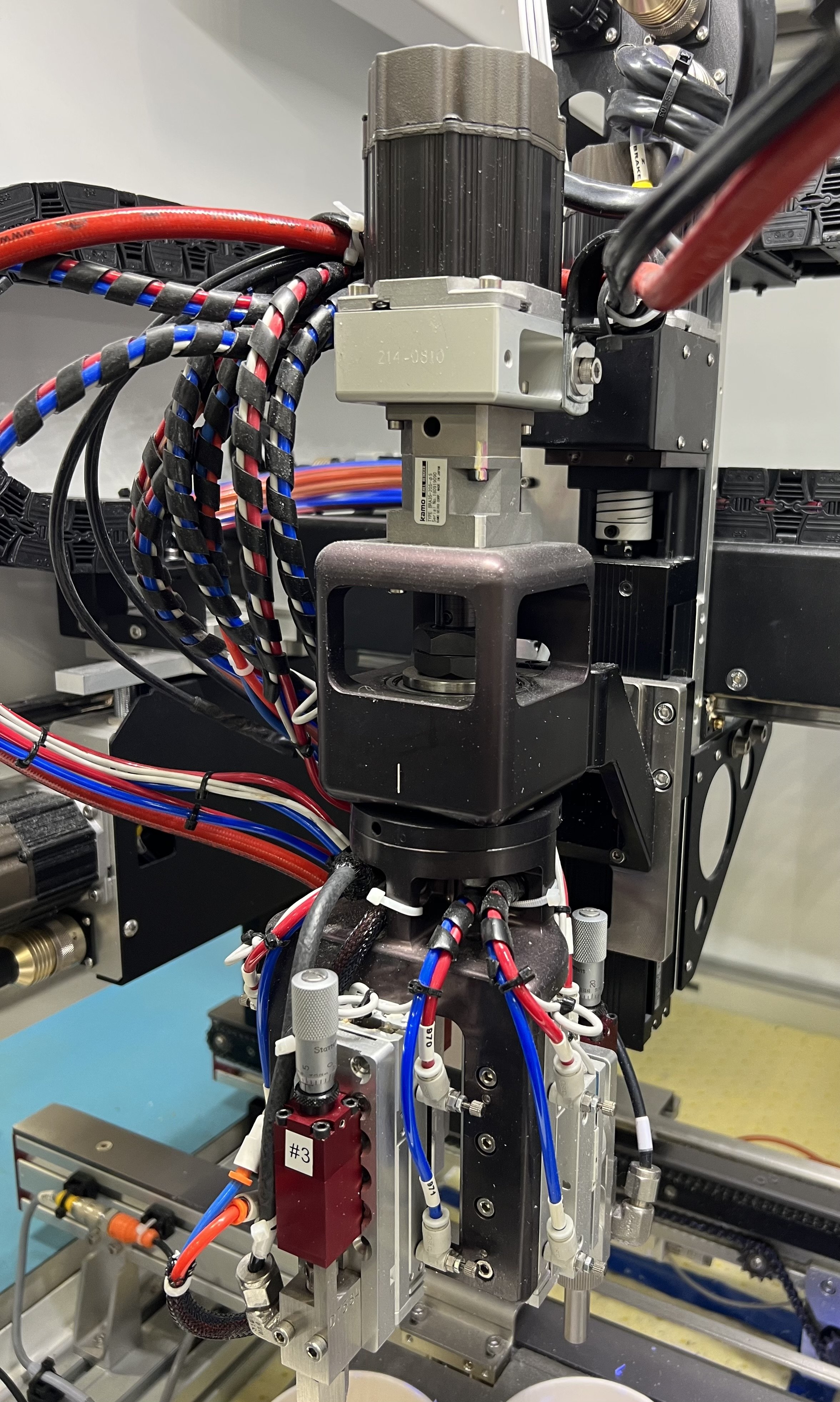

Our IPC-certified technicians apply cutting-edge muti-angle X-ray and automated optical inspection (AOI) to the PCBs we fabricate. We can inspect the integrity of PCBAs and electronic assemblies without the hassle of disassembling and reassembling the components. This electronic testing is a thorough product inspection in a fraction of the time of traditional methods and helps prevent many typical causes of electronic system failure.

Caltronics X-ray inspection is so sophisticated that even our competitors call on us for:

Fast, detailed inspection of BGA solder joints

Finding internal circuit board defects like voiding, shorts, opens, micro-cracks, and ball deformations.

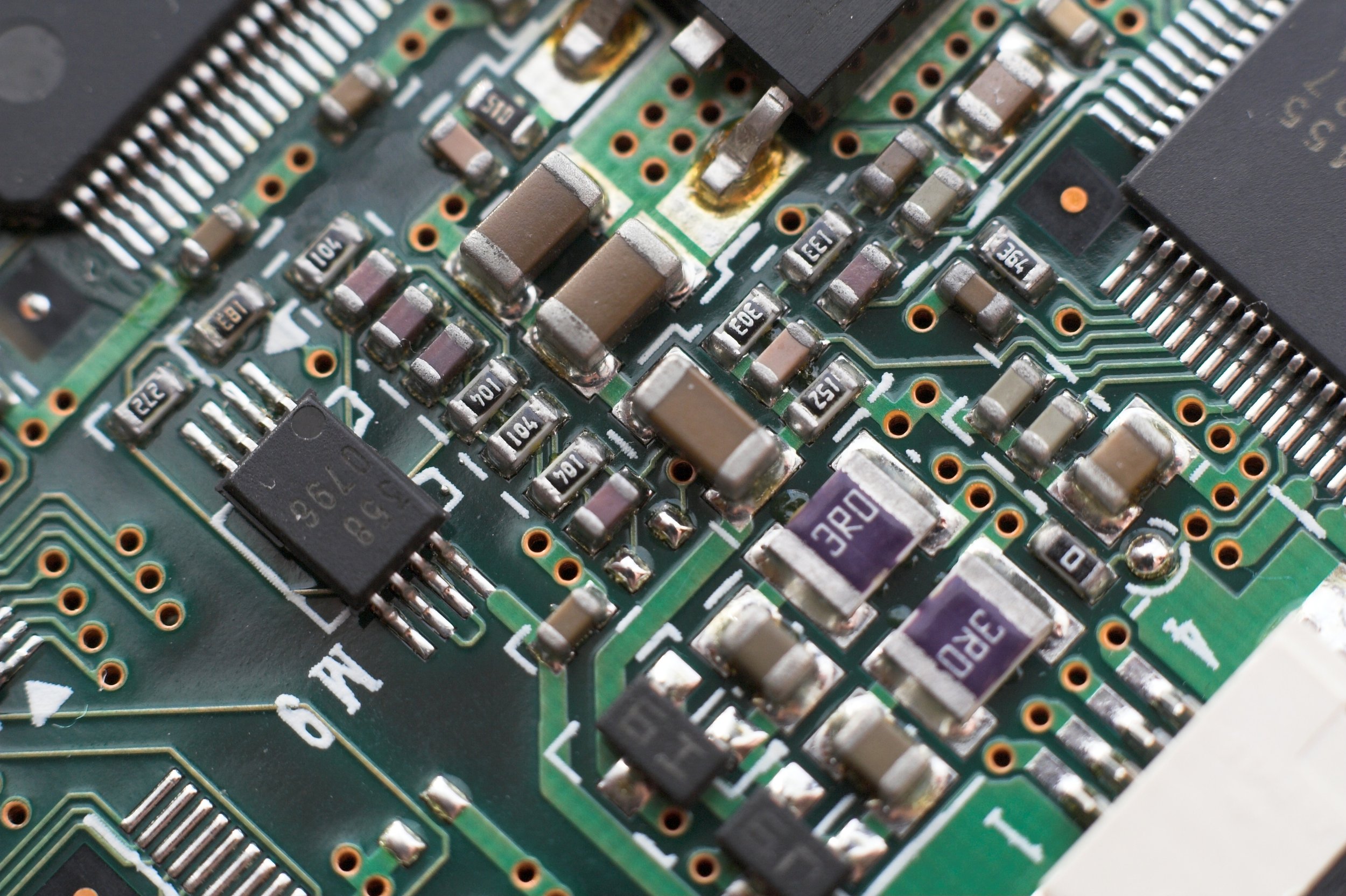

Electronic Testing for Product Design

Thorough testing can ensure that your assembled product is not only going to work but meets applicable federal and industry standards as well. We perform efficient and effective functional testing on your given timeline to ensure your product performs and can pass in an approved lab should you be required to test it by government or industry. Turn to Caltronics for quality assembly services when your end product needs to meet any of these standards:

UL/ETL

Safety testing, certification, and inspection as approved by OSHA.

FCC

Electronic products or equipment comply with appropriate FCC technical standards.

CE

Used to ensure manufacturing conformity for products sold in the European Economic Area.

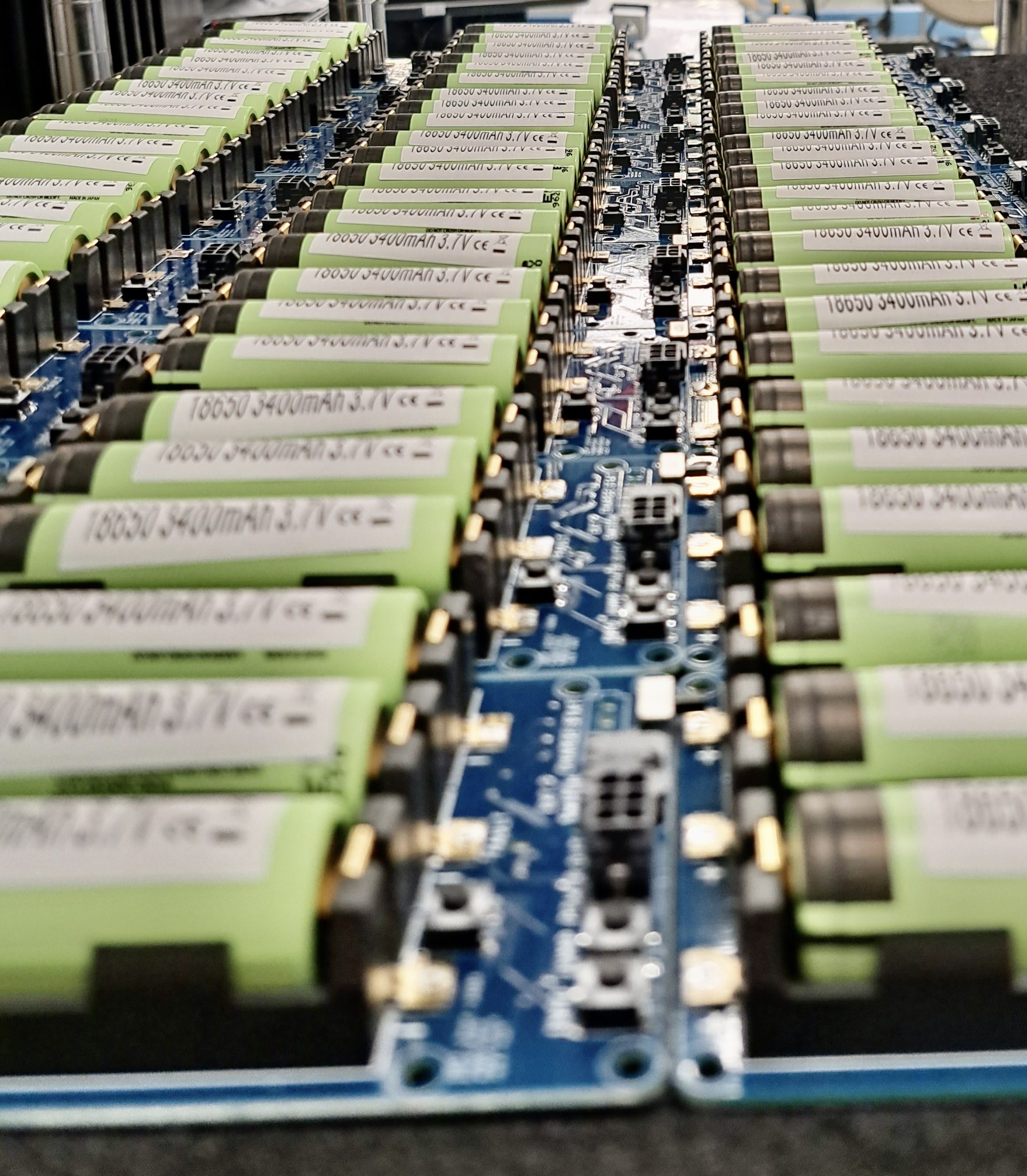

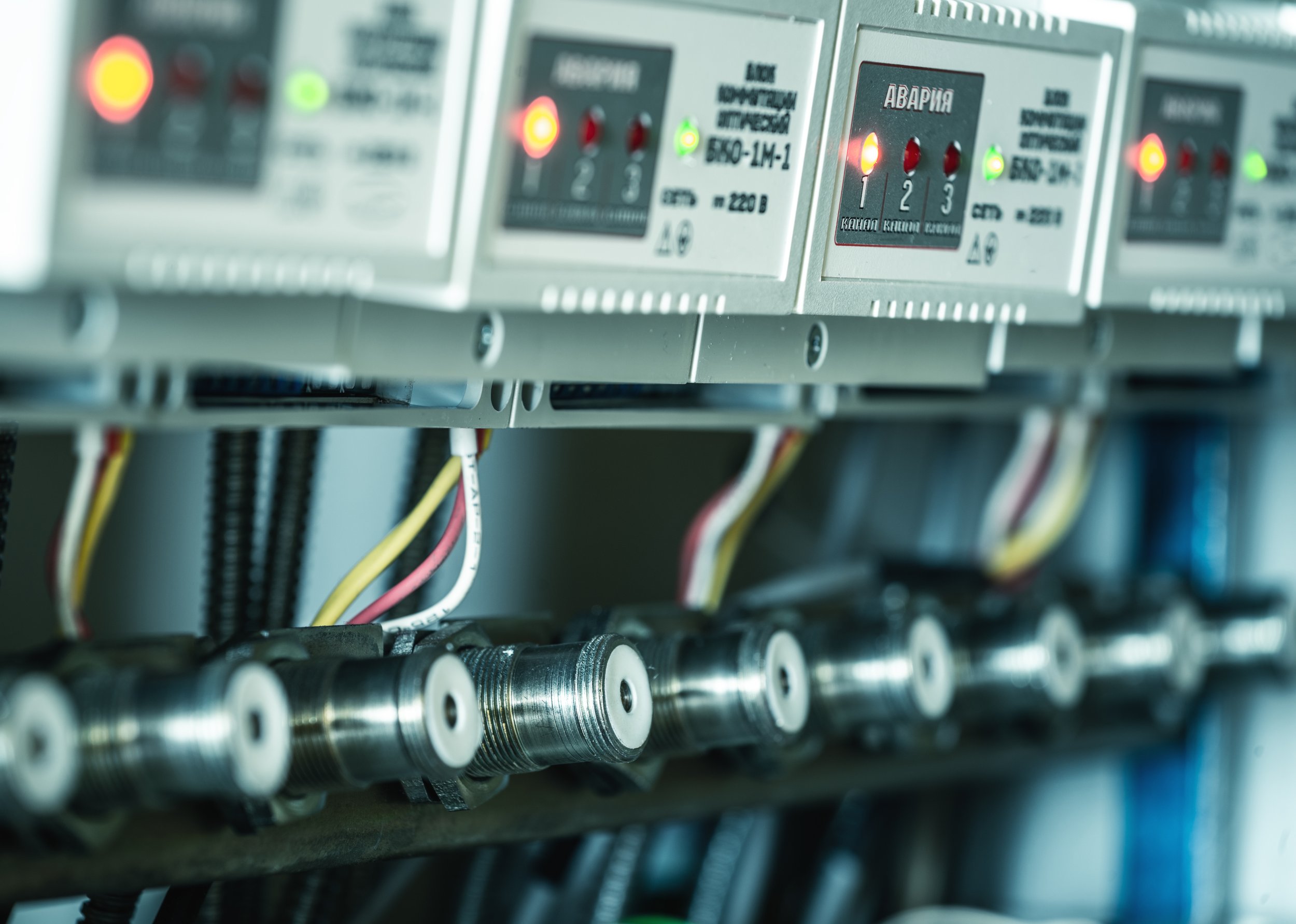

Environmental Testing

Printed circuit boards and electronic products are found across various industries and environments. Every PCB and assembly must withstand the elements of its intended application. Our environmental chamber tests a product’s ability to perform at temperatures ranging from -35 to 110 degrees Celsius.

Industries We Work In

Caltronics Won’t Let You Leave Testing as an Afterthought

Electrical testing is vital to ensure safety and to monitor any defects the printed circuit boards may possess during the design and assembly stages. We at Caltronics test throughout the assembly process to ensure you get the best design possible for your project.