PCB profitability with Design for Test (DFT)

Design for test/testing/testability. Design for manufacture. Design for assembly. Design for…well, you get the picture. There are a lot of “design for’s” to keep in mind. But they all boil down to one concept: design for profitability.

That’s especially important when considering PCB design for test (DFT). PCBs can be complex, and they’re expected to work without errors. Inspection and testing are essential to PCB manufacturing but can be time-consuming and costly.

How can you accommodate inspection and testing requirements and keep a product profitable?

The secret to PCB perfection (shhh, it’s inspection and testing)

The electronics business is made up of serious perfectionists whose basic assumption is that devices will perform flawlessly time after time. But perfection is hard to come by.

In the real world, a printed circuit board’s many components and solder joints must meet design specifications exactly for the PCB to function properly. To ensure perfection, inspection is a critical part of PCB fabrication.

What PCB inspection methodologies are there? Which ones will work best for your project? All you need to know is in our white paper.

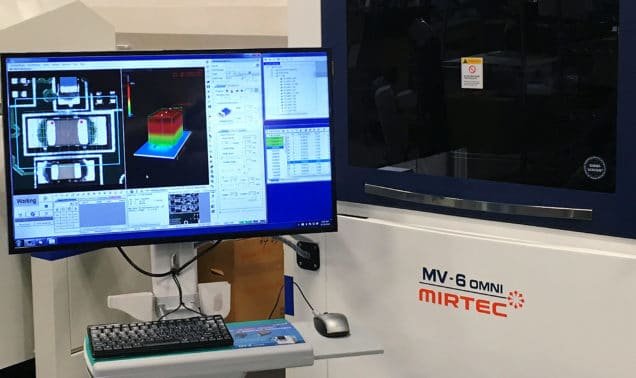

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016 Caltronic’s own Cal Houdek, and Brian D’Amico, President of MIRTEC, at SMTAI 2016 Circuit Board Visual Inspections just got that much better with our newest addition, the MIRTEC MV-6 Automated Optical Inspection Machine. Caltronics is proud to announce our purchase of a MV-6 OMNI machine.

Get What You want from Your PCB Team

At Caltronics we have found the importance of communicating clearly with our clients to make sure the product they receive accomplishes what they need and want it to do. That’s why our PCB teams are so important to us and our clients.