Design for Test

How Does Design for Test Change The Way Your Product Is Made?

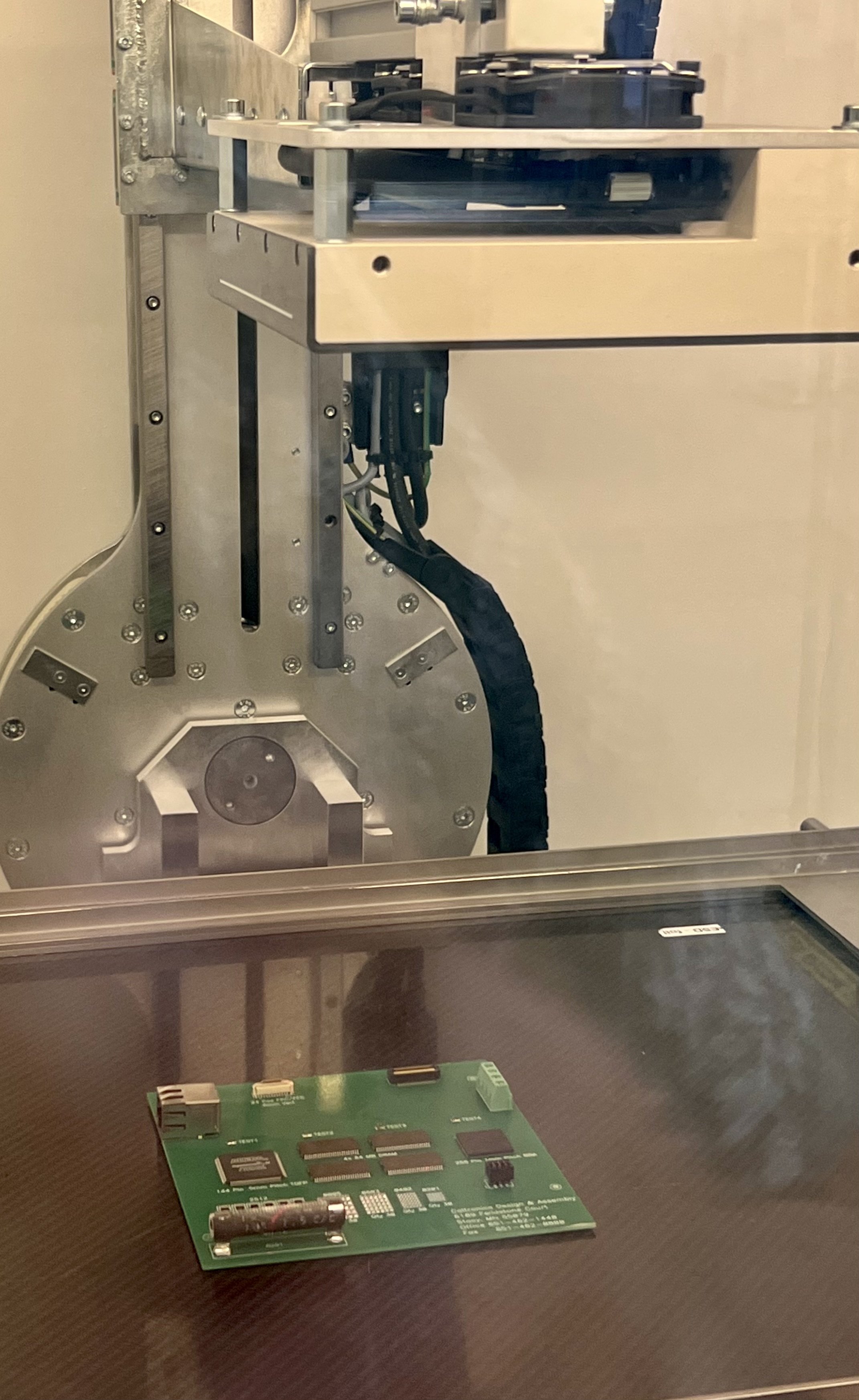

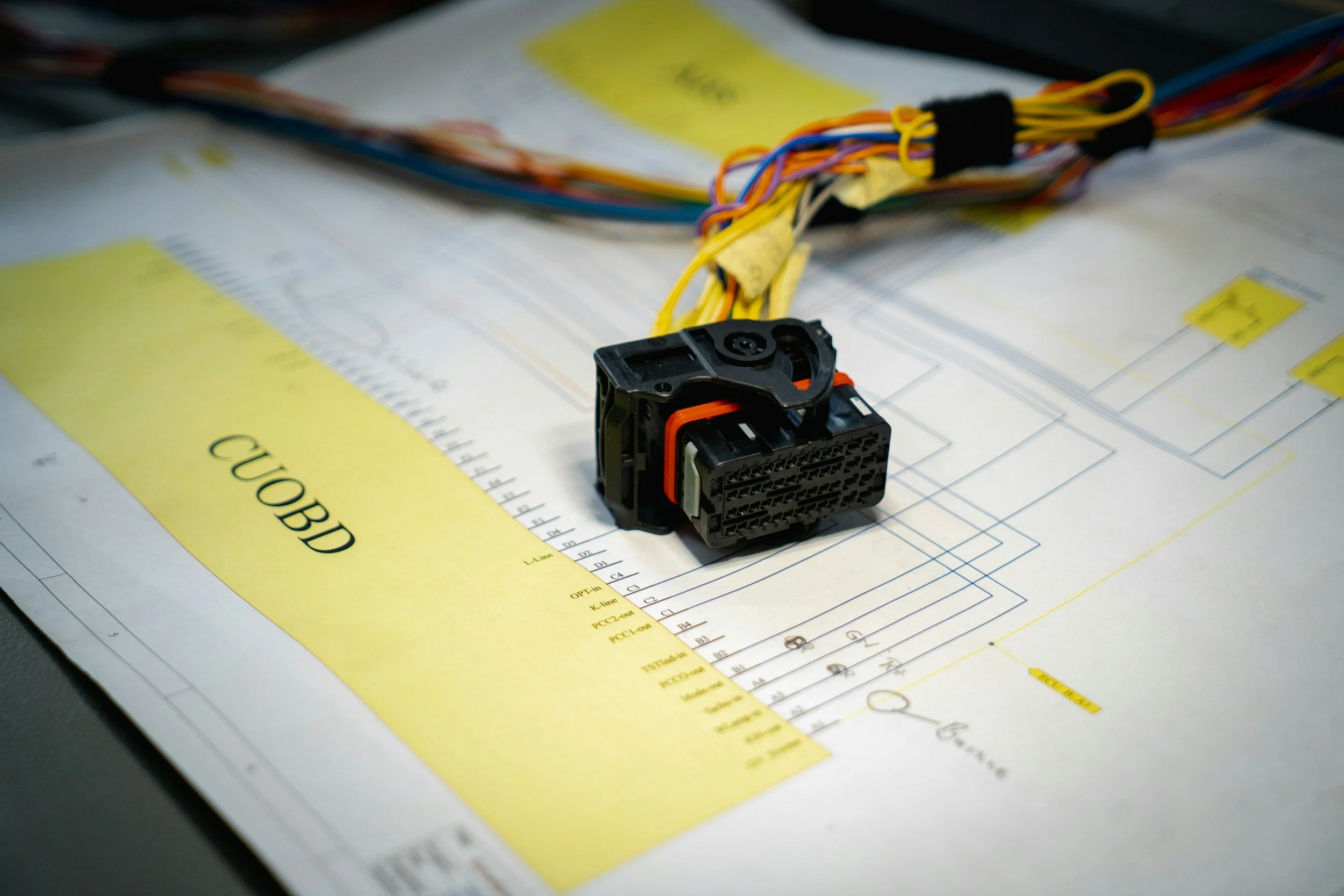

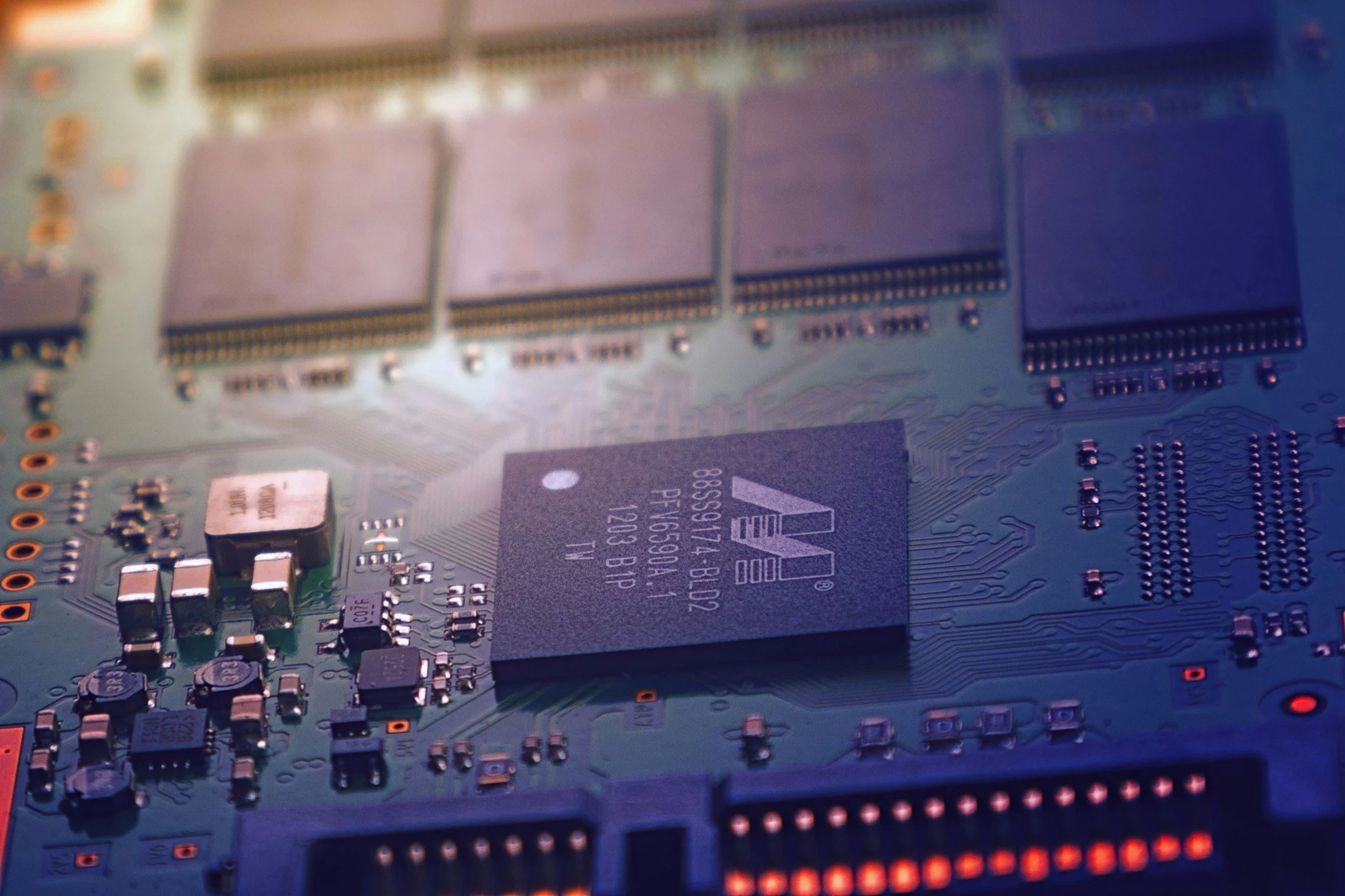

Testing and inspection are not just final checks, they are part of the entire design and assembly process. Our design for test (DFT) method helps create a functional and reliable PCB product by planning for testing early in the design phase.

Designing with testing in mind from the beginning helps avoid redesigns, reduces delays, and keeps costs under control. Every design is reviewed to make sure it can be inspected and tested easily and efficiently.

What is Design for Test and Why Does it Matter?

The DFT approach helps ensure that the product works exactly as intended. Under this approach layouts may be developed with inspection access, test points, and clear assembly paths. This allows for testing during production instead of after the fact. The result is:

Fewer revisions

Faster builds

Higher product quality

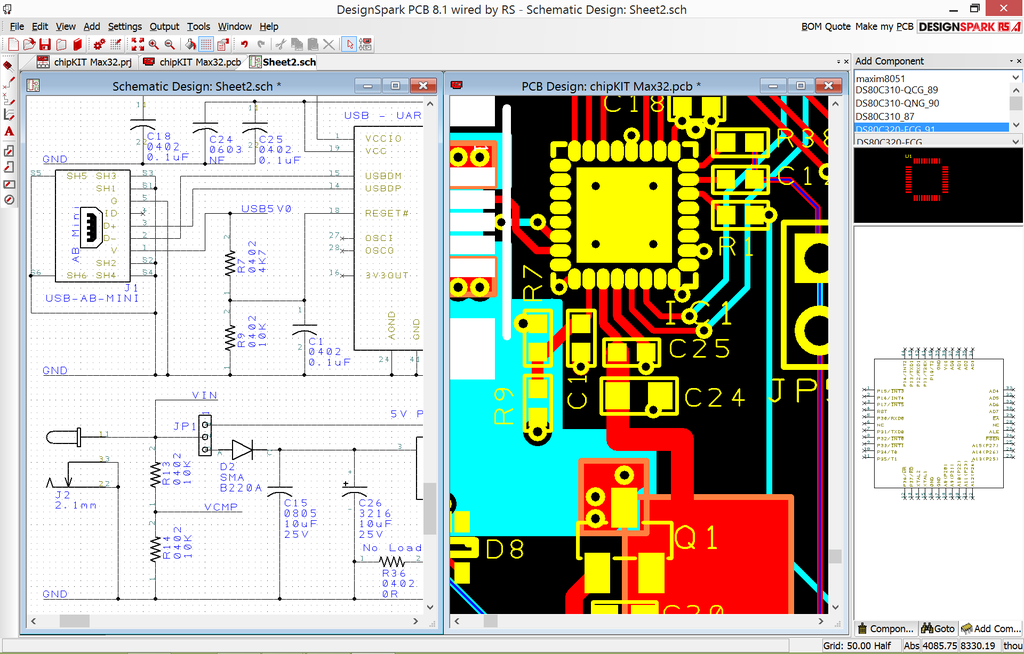

Planning for Test During the Design Phase

DFT starts with understanding how the board will be assembled and tested. Each layout is planned to reduce the number of steps between design and delivery, including:

Analyzing the best way to route and assemble the board

Including built-in testing access and electronic checkpoints

Reviewing and improving based on customer feedback

This process creates a design that’s ready for fast and accurate testing during manufacturing.

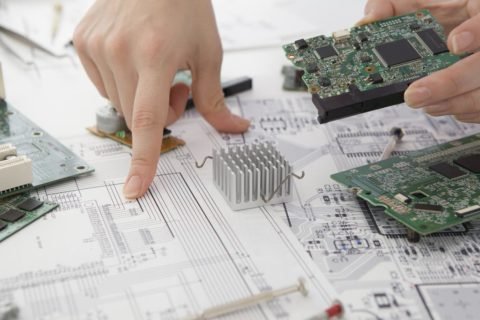

Working Side-by-Side with Customers

The DFT method includes ongoing customer input throughout the project. Feedback is built into each stage to ensure the design stays aligned with the original vision. Customers help guide the process by approving designs, suggesting adjustments, and making sure the final product matches their needs. This collaboration improves outcomes and eliminates surprises.

Markets We Serve

Common Design for Test Questions

-

By keeping the final product in mind from the start, testing requirements are already built into the design. This reduces time spent reworking or troubleshooting during manufacturing. Once the design is approved, production can move forward with fewer delays.

-

DFT can be applied to both simple and complex electronics. It is especially valuable when deadlines, budget, and performance are critical. This method helps control costs, reduce errors, and streamline production.

Your Test-Ready Design Starts Here

If your next product needs to meet high expectations for performance and reliability, the DFT method helps you get there. Build testing into your process from the beginning to save time, reduce costs, and meet customer requirements.

Get Started with Caltronics Today

Ready to turn your innovative ideas into reality? Fill out the form below or call us at 651.462.1440 to learn how we can assist you in achieving your goals.

Related Services