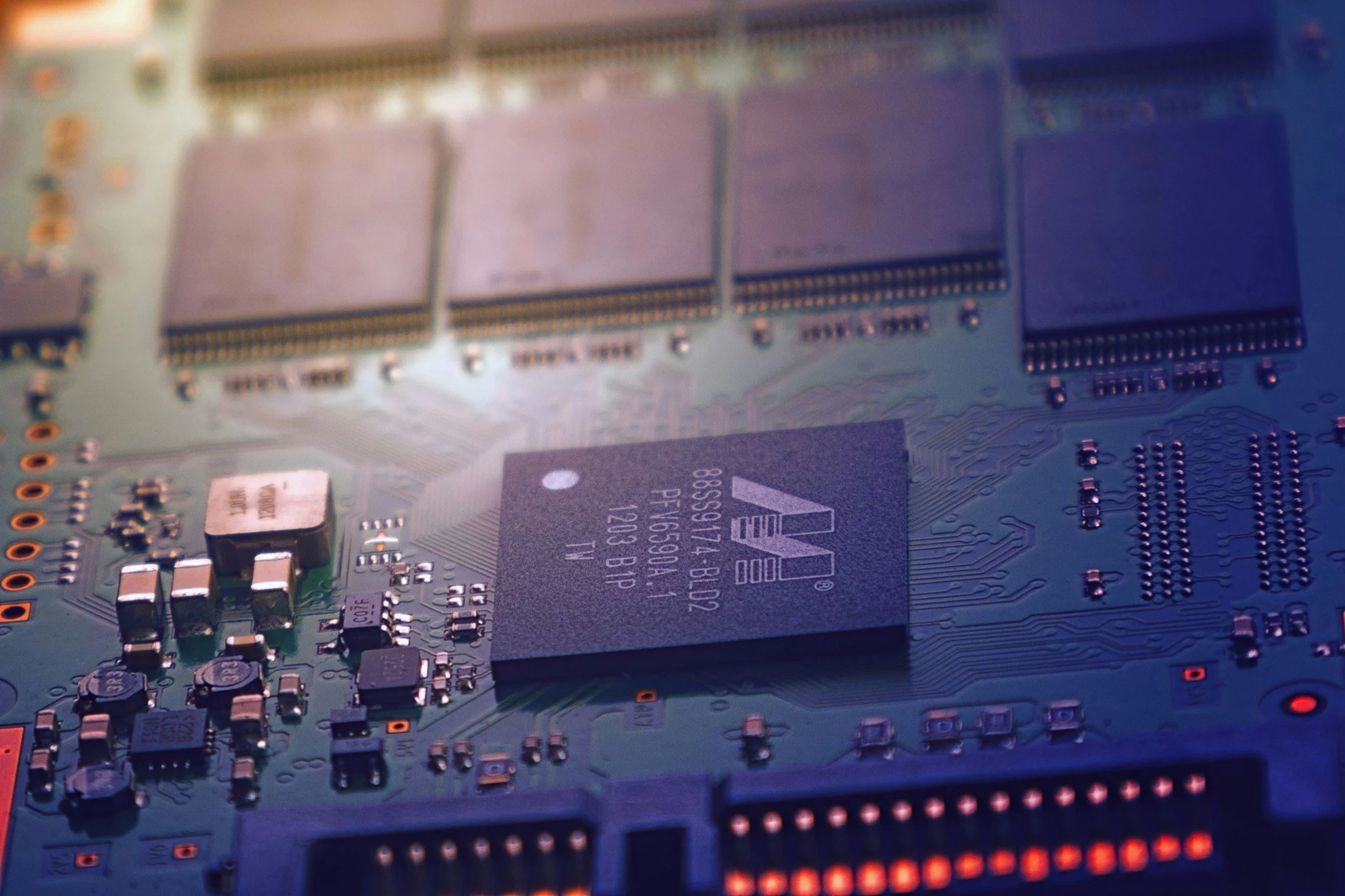

PCBs Designed for Manufacturing from the Start

Designs for Real-Life Applications

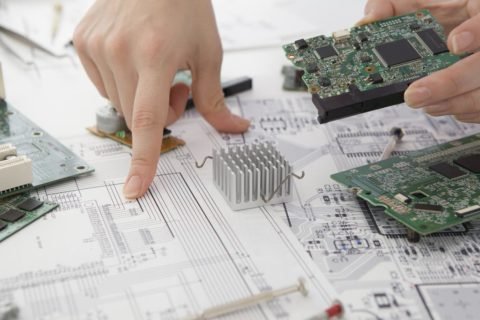

PCB design for manufacturing (DFM) creates PCBs by incorporating the requirements for manufacturing the physical PCB into the design. While PCB schematics may be designed using software on the computer, there are essential components that can only be replicated and tested by creating a physical prototype.

We evaluate the device constraints and the process for assembly. We ensure we stay ahead of industry standards, and our design for manufacturing service considers every factor that goes into the manufacturing process to make a functional and production ready device every time.

PCB Design for Manufacturing from Start to Finish

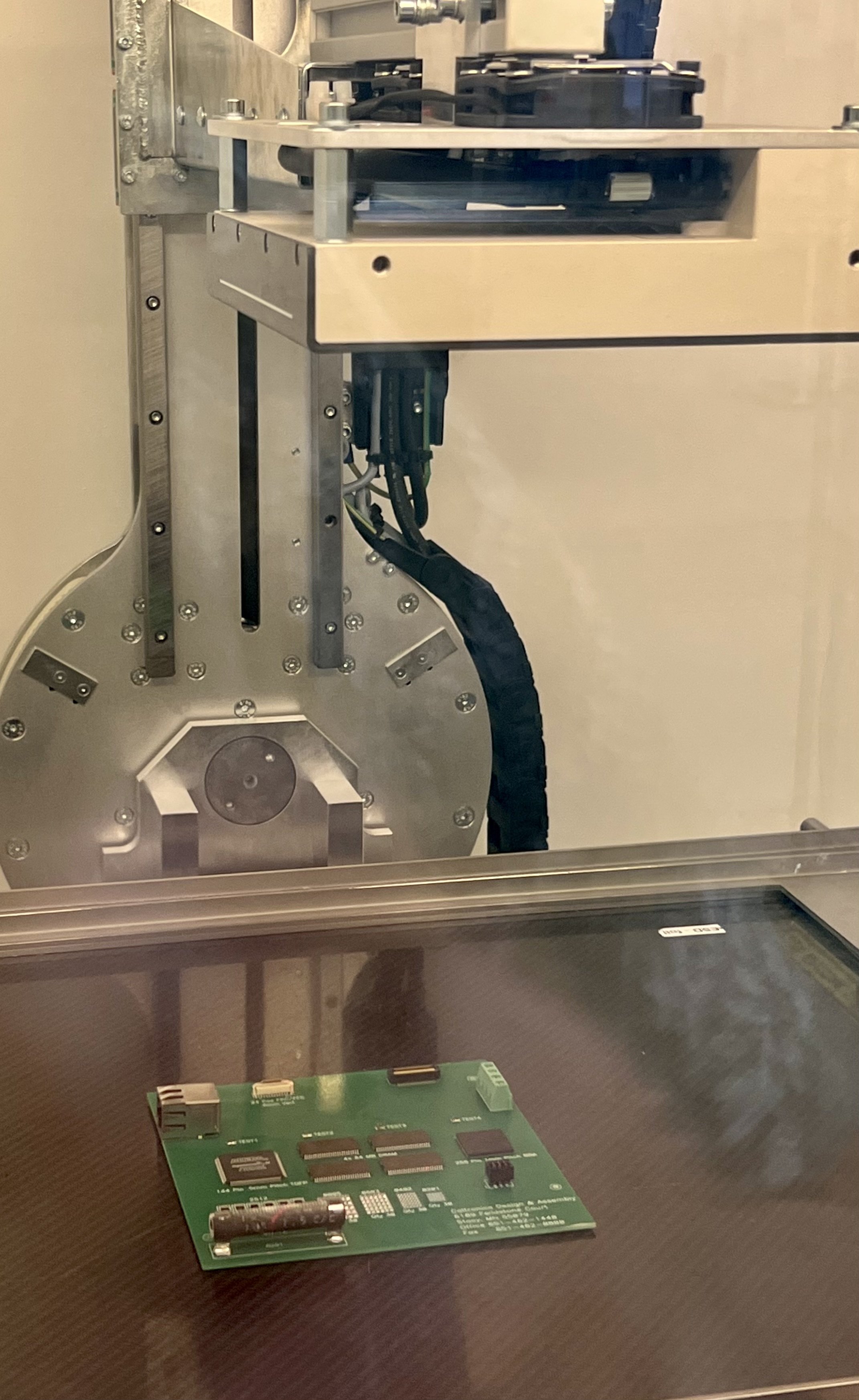

Not only are we your PCB design partner we are your partner from the start of the project to final production and shipping. Our electrical engineers on staff can develop the original designs for a PCB and oversee the assembly process.

Our electrical engineers have decades of experience designing PCBs for manufacturing, so they understand the considerations that go into manufacturing and assembling the PCB. Since Caltronics can handle each phase of the PCB Assembly process, your project is handled by the same team from start to finish.

PCB Design for Manufacturing (DFM) Services Built with Cost-Efficiency in Mind

We are a full-service company that specializes in:

PCB Design

PCB Testing

PCB Assembly

These three factors allow us to understand the full scope of production costs. When we design a PCB, we consider the production processes, component costs, and supplier agreements. We optimize each design for manufacturing by looking at cost-effective and efficient ways to achieve your goals. Testing also allows us to detect potential issues or corrections that need to be made before mass production.

Designing Products that are Ready for Market

At the core, our design for manufacturing is a scientific process of planning and creating. We develop a strategy to manufacture a specific product that matches your specifications. Design for manufacturing impacts all industries and individuals developing devices because every step of the manufacturing process needs to be incorporated into the PCB design to create a functional product.

Markets We Serve

Common Design for Manufacturing Questions

-

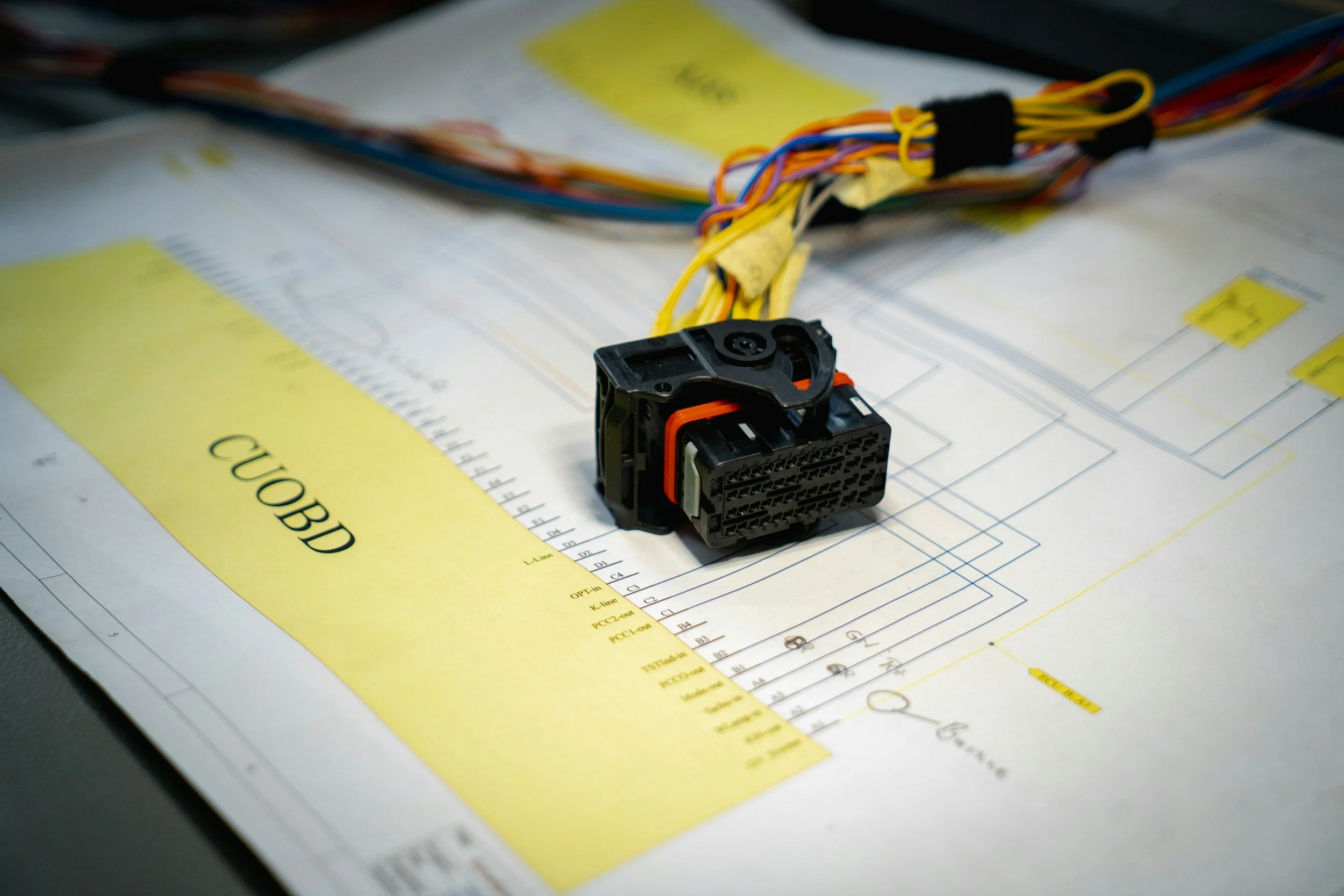

PCB designs only created on a computer can miss simple functions vital to the product's final goal. By designing for manufacturing, we can better examine how the product will work compared to a strong estimate.

-

Water-Resistance

Hostile Environments

Radio Wave Interferences

External Trigger Barriers

Spatial and Structural Awareness

Start Your Project with Manufacturing in Mind

Our designs exceed the limitations of the computer screen and include the necessary components needed for manufacturing. We develop methods equipped with the specifications needed to streamline your product from design to manufacturing.

Get Started with Caltronics Today

Ready to turn your innovative ideas into reality? Fill out the form below or call us at 651.462.1440 to learn how we can assist you in achieving your goals.

Related Services