Jet Soldering

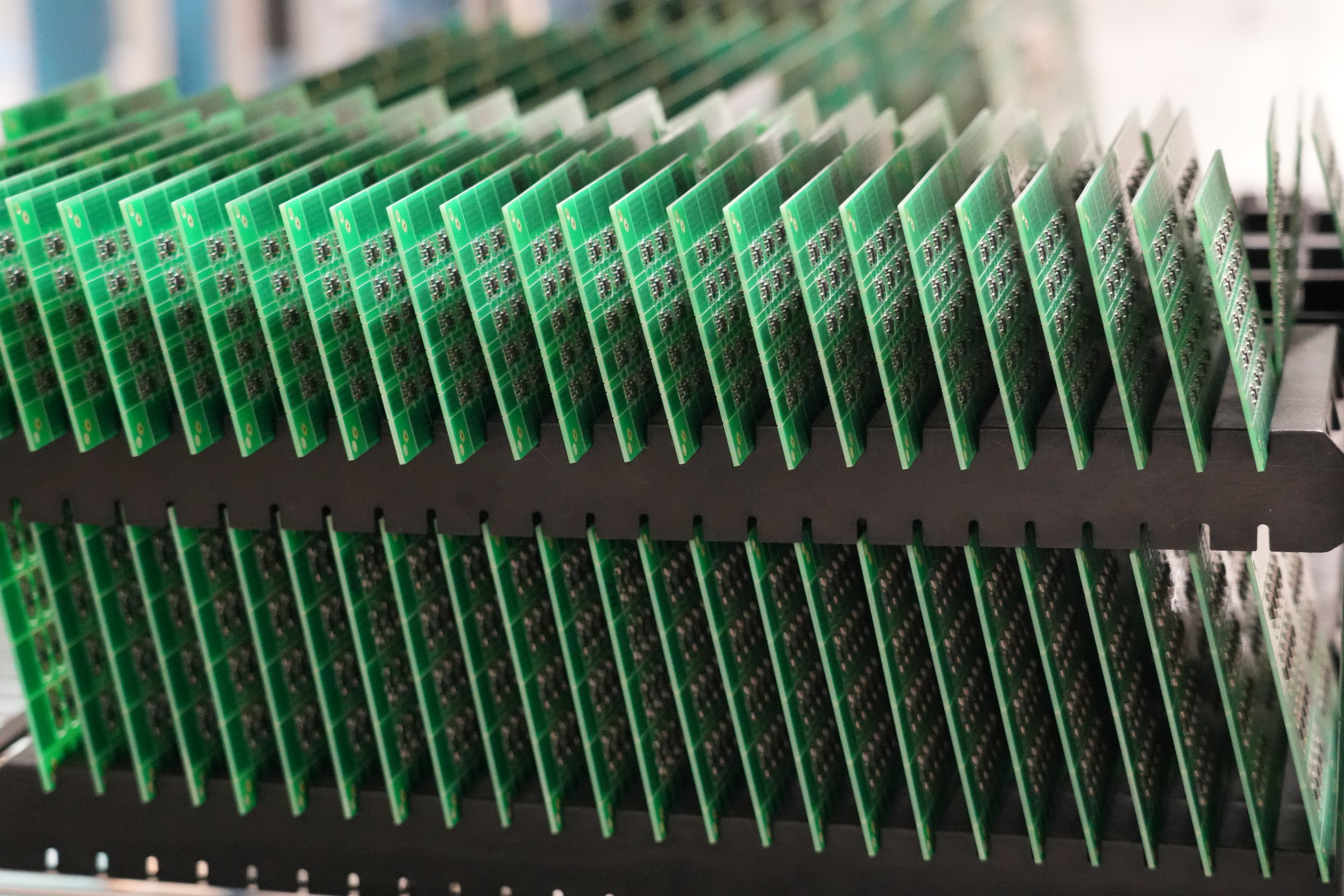

Jet Soldering for PCBs: Precision Paste Deposition Without Compromise

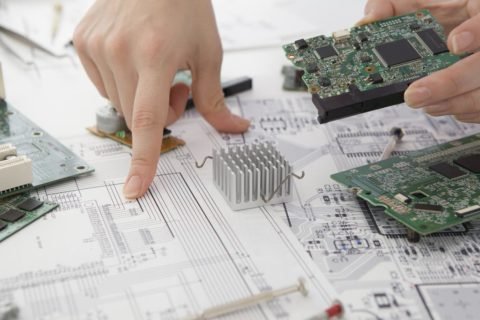

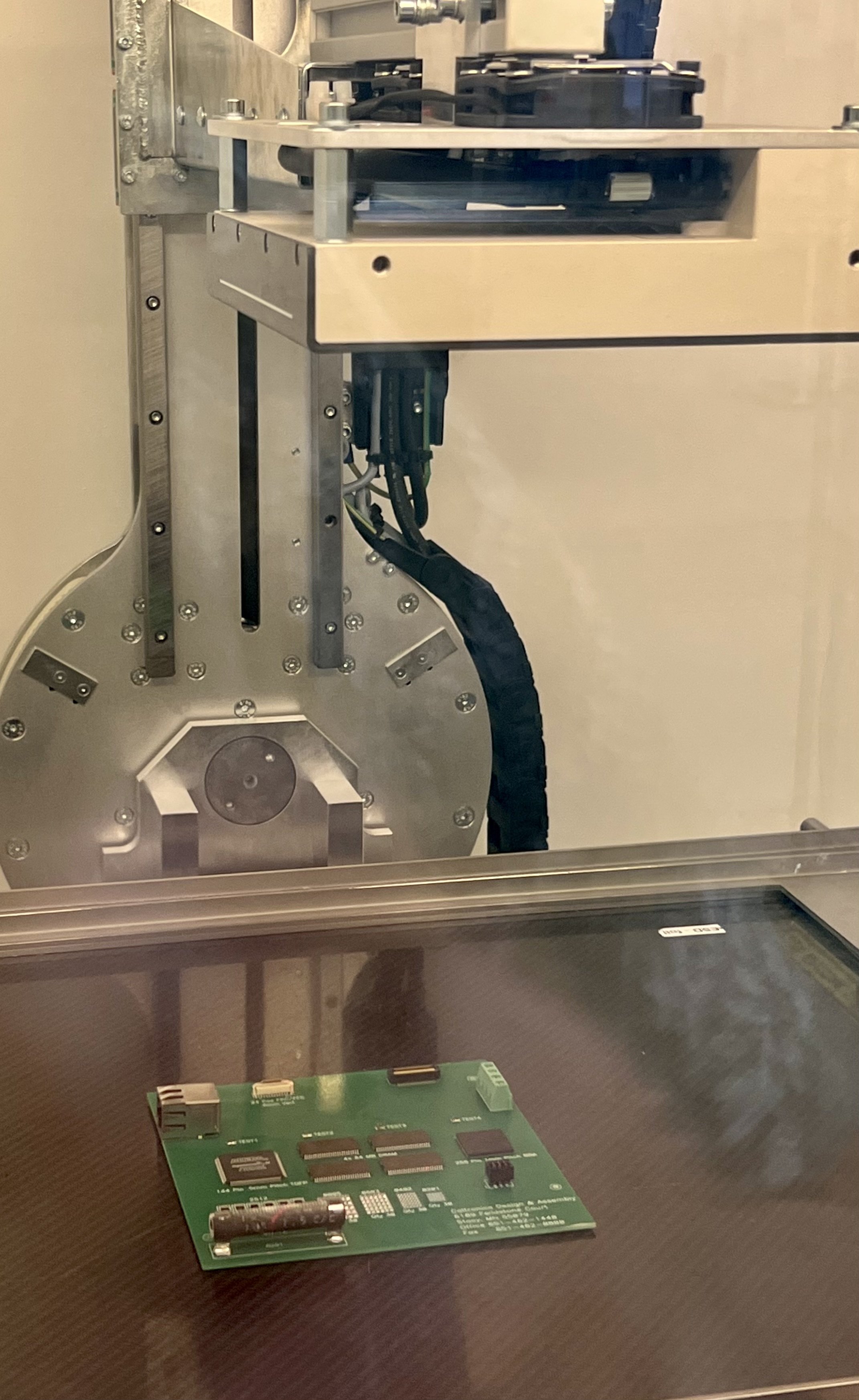

Jet soldering is a high-speed, non-contact method for applying solder paste with exceptional accuracy. This technology is ideal for printed circuit boards that feature fine-pitch components, irregular surfaces, or require selective soldering without the need for custom stencils.

Jet soldering supports rapid prototyping, low- to mid-volume production, and advanced assemblies where flexibility and precision are critical. It enables engineers to adjust paste volume and placement dynamically, improving consistency and reducing waste.

Benefits of Jet Soldering

No stencil required, reducing setup time and cost

High placement accuracy for fine-pitch and micro components

Adjustable dot size and volume for tailored soldering

Ideal for boards with uneven surfaces or mixed technologies

Supports fast design iterations and engineering changes

Jet Soldering is Well Suited for

Prototype builds with frequent revisions

High-density layouts with tight spacing

Assemblies requiring selective solder paste deposition

Boards with 3D components or non-planar surfaces

Mixed SMT and through-hole designs

Markets We Serve

Why Choose Caltronics?

Jet soldering enhances process control and repeatability, especially in environments where traditional stencil printing is not feasible. It supports complex board designs and helps reduce defects by ensuring consistent solder paste application. Ready to learn more or get started today? Caltronics is ready to help!

Get Started with Caltronics Today

Ready to turn your innovative ideas into reality? Fill out the form below or call us at 651.462.1440 to learn how we can assist you in achieving your goals.

Related Services